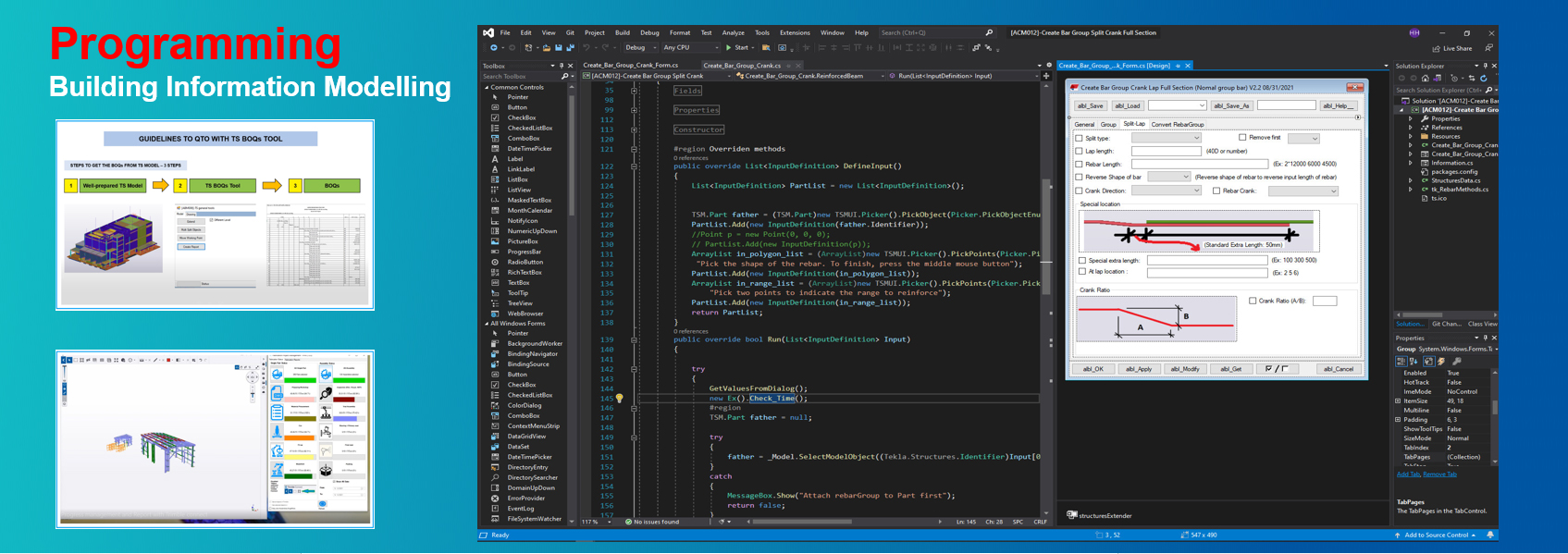

Each company has its own technical specification & requirements as well as working procedure. Based on the individual needs, iCEB Solutions is providing the service to write the programs, plug-in, automation tools & mini-software for the clients who are using Tekla & Revit mainly to manage the works in the best way, regarding the QUALITY, TIME SCHEDULE & COST in different working steps:

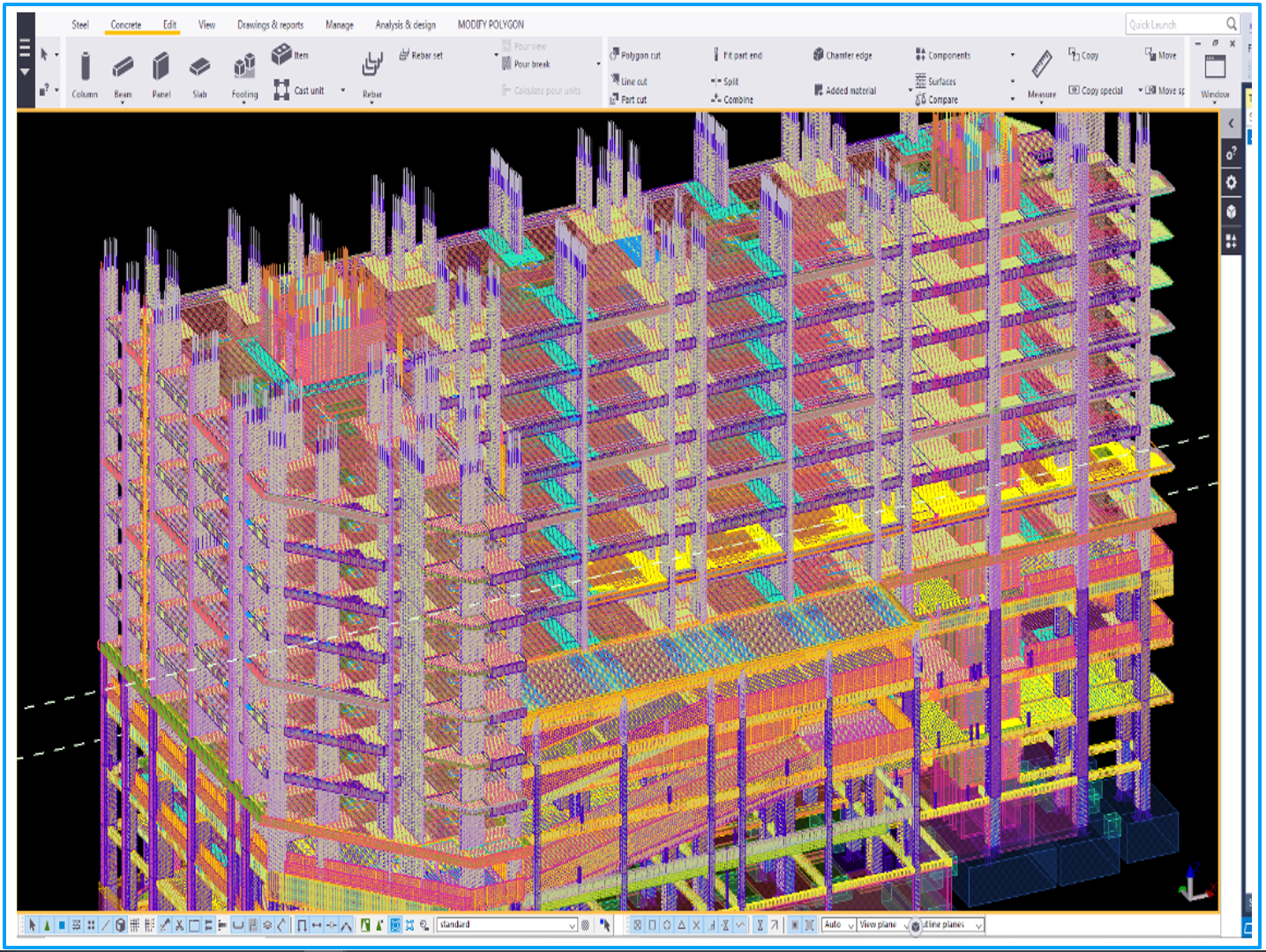

Automation tool for 3D modelling & 2D drawings of concrete/ rebar works

Automation tool to export data from 2D/ 3D software such as Autocad, Sap2000, Revit, Tekla Structures, etc. to another 3D software.

In case the input data is organized in a high standard way, the tool will save considerable time of the works.

Automation tools for 3D rebar modelling of foundations, columns & beams. The tools save considerably time and provide high quality 3D rebar model.

Automation tool to group, split, lap and crank the rebar following project standards.

The tool is very useful in order to achieve a clash-free model or at least, a model without major clash between rebar, which helps the works in the construction site running much more smoothly.

Automation tool to generate the rebar drawings of columns.

Automation tool to generate the rebar drawings of beams.

Plug in to build the 3D model and generate 2D drawings of standard man-holes from design input in excel spread sheet

The lost rate for rebar cutting can be optimized directly in the 3D model until expected level for defined area. The tool can also point out the cutting combination, lost rate for each rebar diameter as well as the overall lost rate ratio. The figures can be generated to excel file or text file for next steps of rebar cut & bend activities.

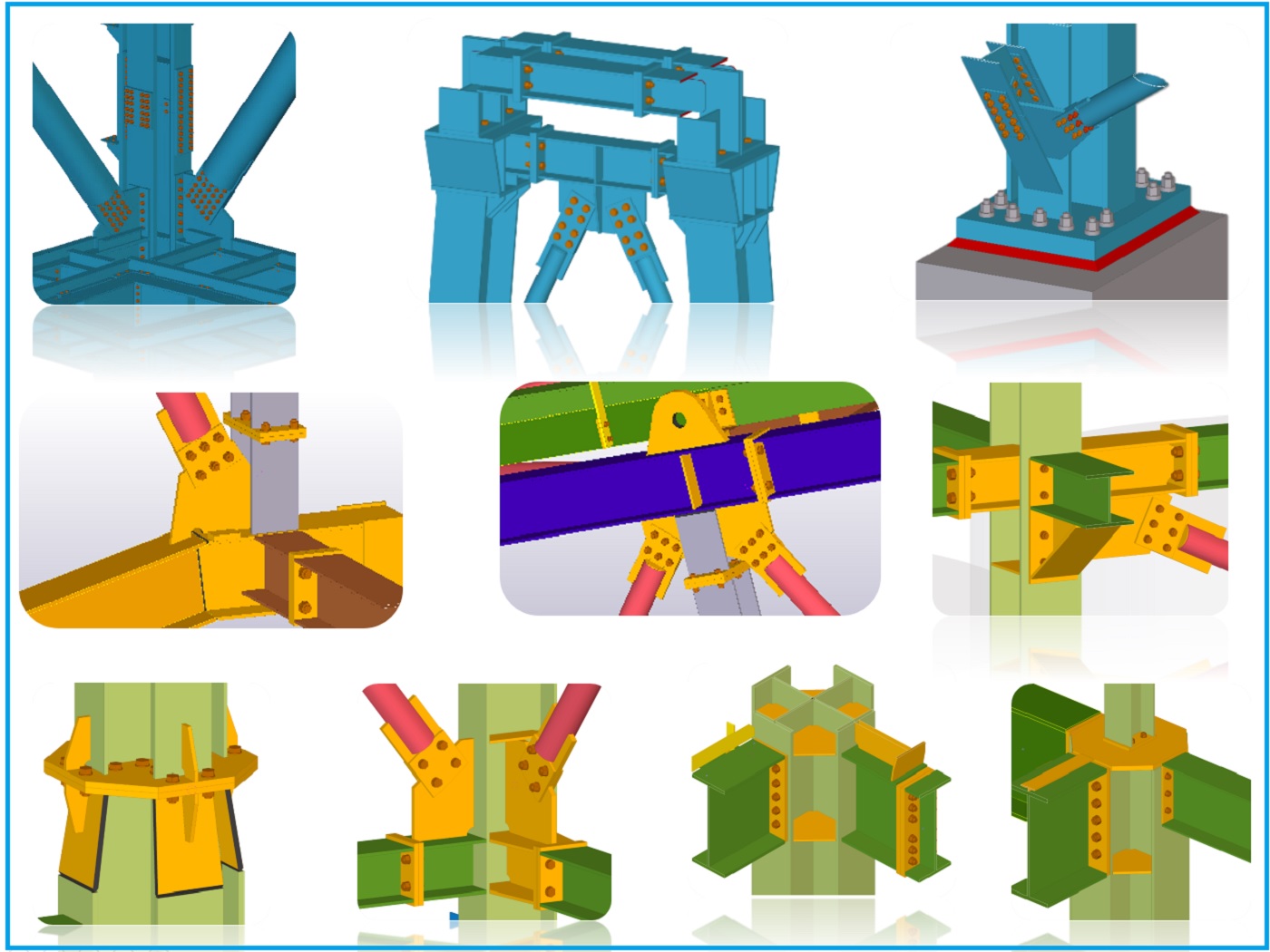

Automation tool for 3D modelling & 2D drawings of structural steel

Automation tools for steel modelling and drawings

Automation tools for conveyors in the heavy industrial plant

Plug-in to build the 3D model of the roof of one international airport

Management in design, construction & fabrication

Progress control: The progress of the steel structural fabrication works in the factory can be controlled well following 3D/ BIM concept for different steps, including: workshop drawings, material procurement, cutting, fitting up, welding, inspection, trial assembly, blasting, coating, packing and transporting.

The data can be generated to different 2D reports with detail level required.

The progress control for rebar processing work in the off-site plant is similar to the application for structural steel in the workshop.

The working steps here consist of workshop drawings, material procurement, cut & bend, marking, packing and transporting.

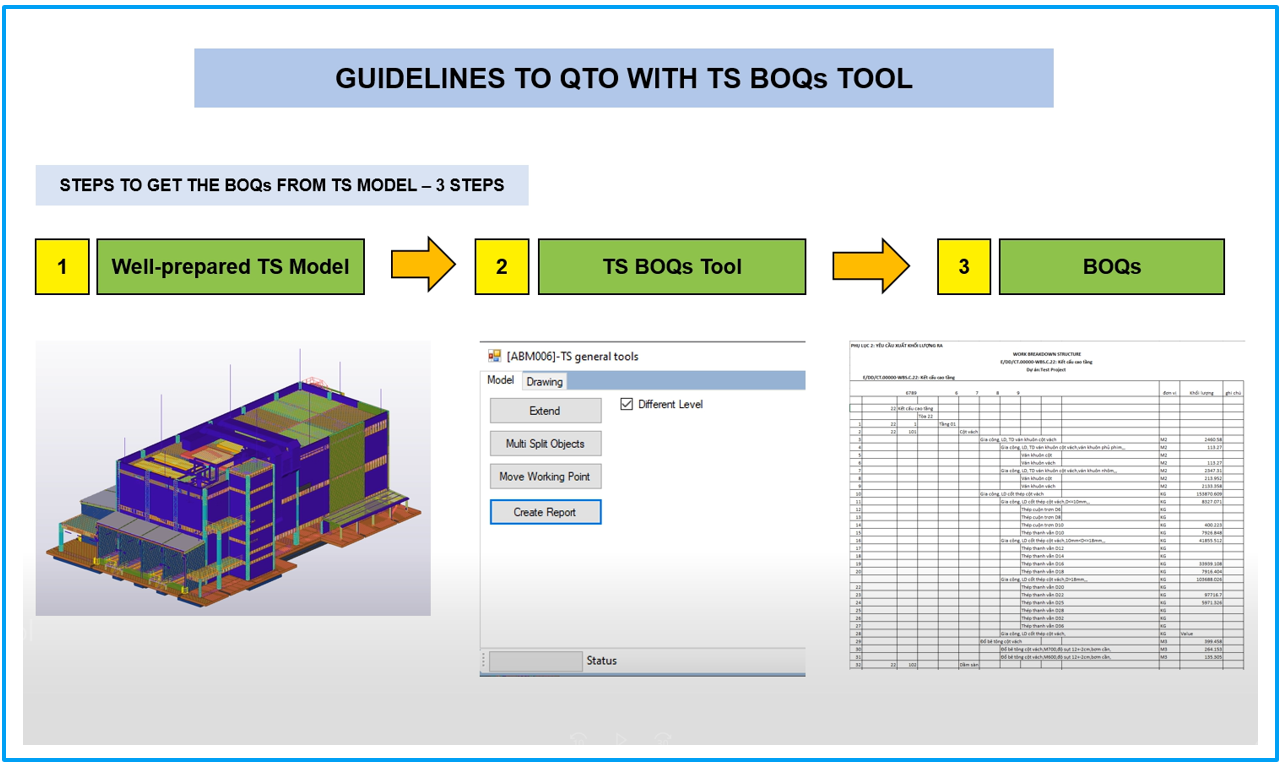

Quantity/ Price Control: The quantities can be generated automatically from 3D model to the required Bill of Quantity form, thanks to a plug-in and the fact, that the data in the 3D model is well organized following company standards.

The quantities then, can also be exported to the required pricing software for price analysis.