The detail information for BIM Structural steel detailing is similar to the contents for BIM rebar detailing. We only mention here some different points:

Procedure

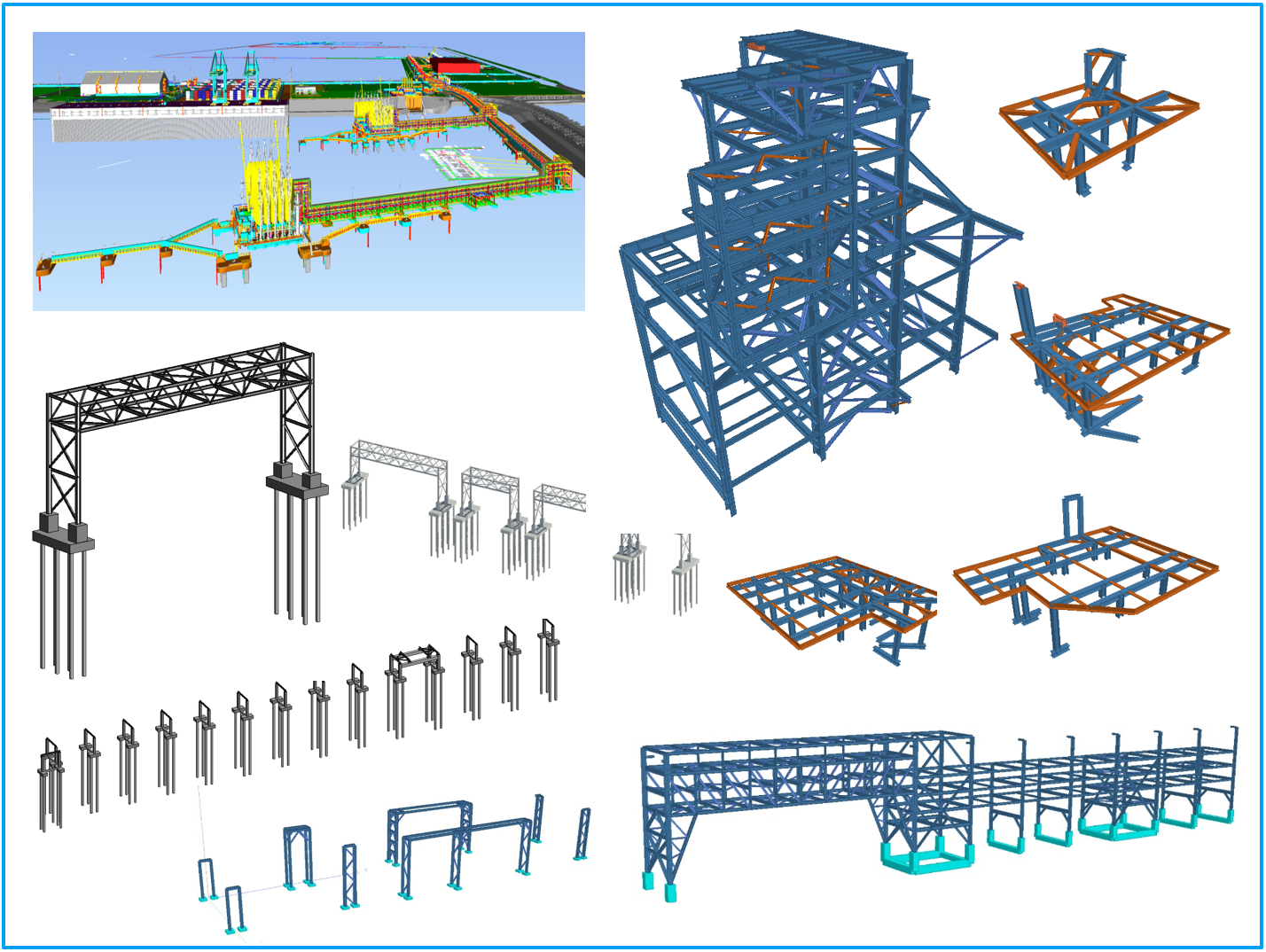

As part of the full service for Civil & Structural Steel Engineering & Detailing, we are also providing the service ‘’Workshop modelling & drawings for structural steel’’ with below workflow. The input data from client for this service is the basic engineering with all steel members forces. Bases on that, our services will be divided into 4 main steps including connection calculation, modelling all details in one 3D model, issuing workshop design package (WDS) and generating erection drawings. Each steps will be controlled by QA/ QC department and then, submit to client for approval.

Step 1-Connection Calculation:

The main software for this step are Limcon & RAM Connection. The output of this step is the sketch showing the connection details such as number, diameter, arrangement of bolt, welding parameters, etc.

In some case, client provides also the connection calculation and the step 1 is skipped.

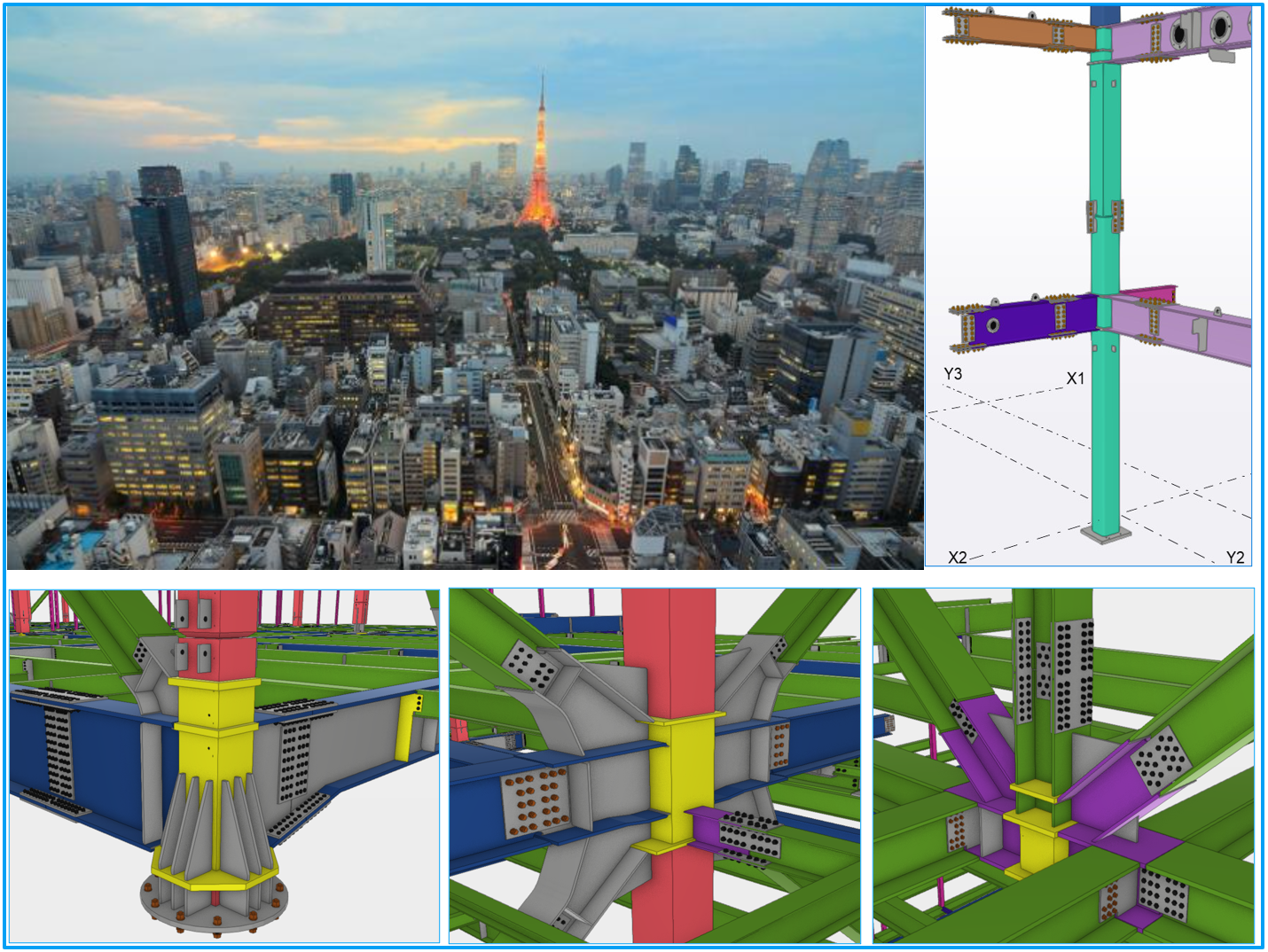

Step 2-Modeling:

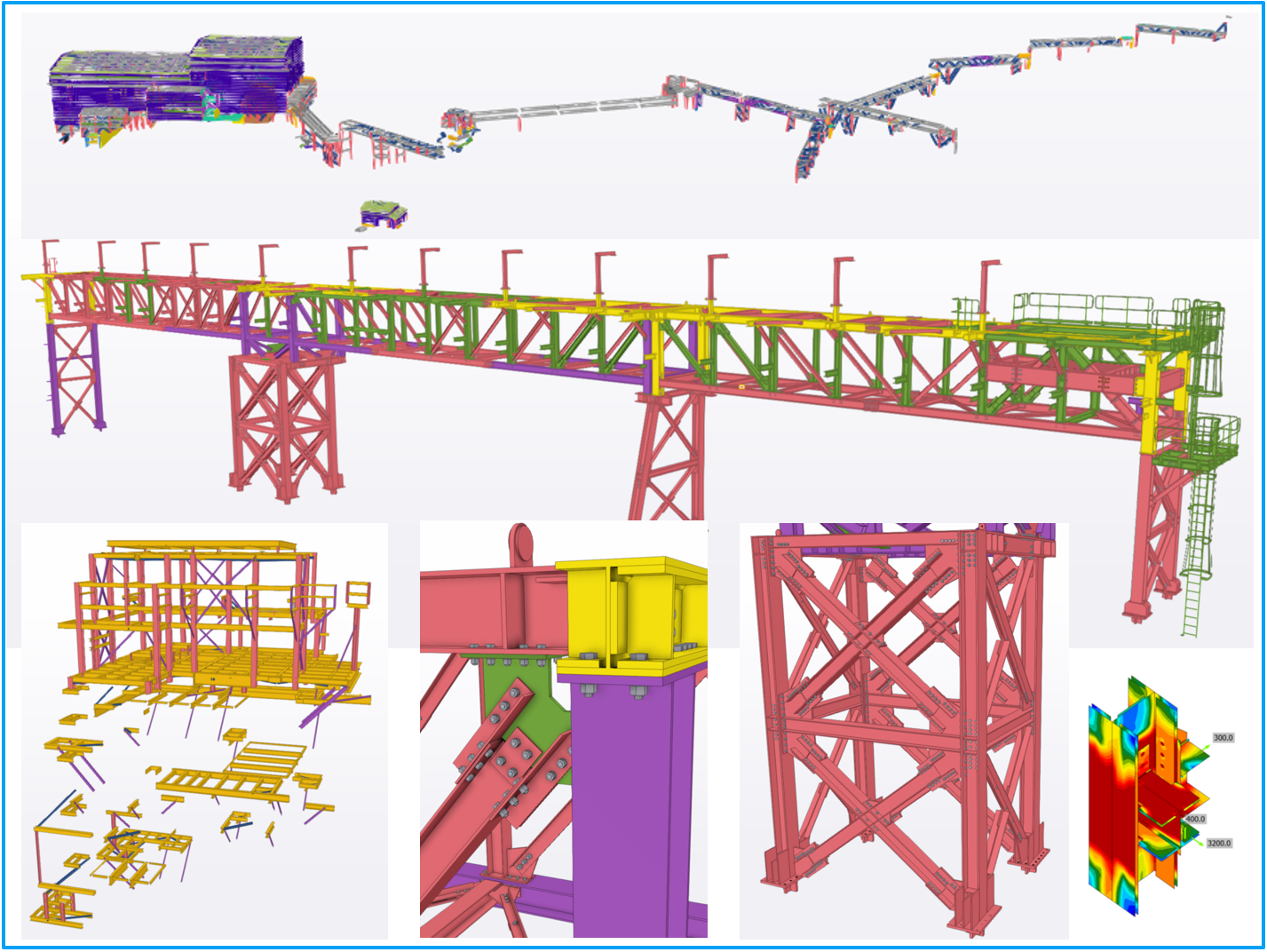

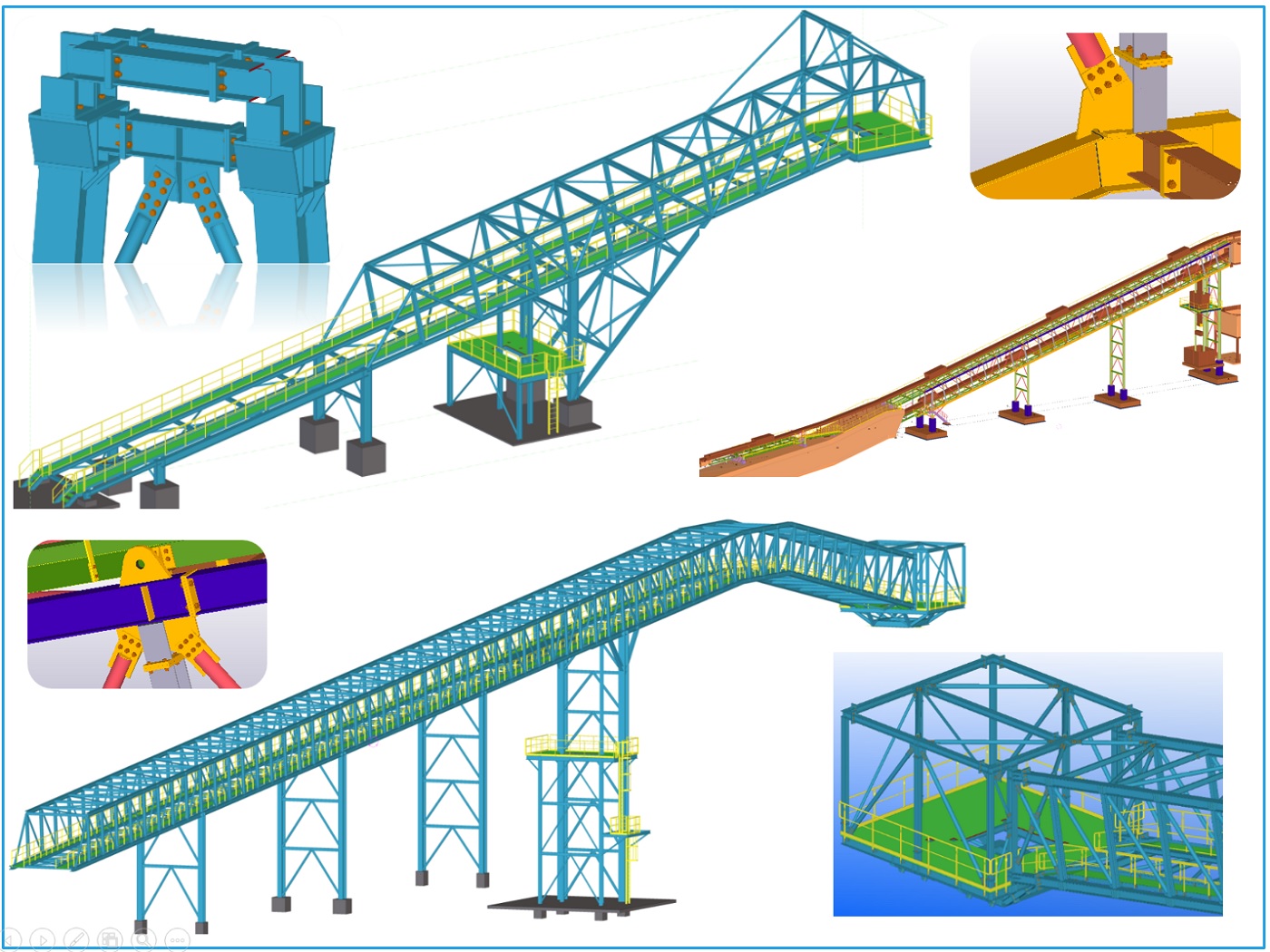

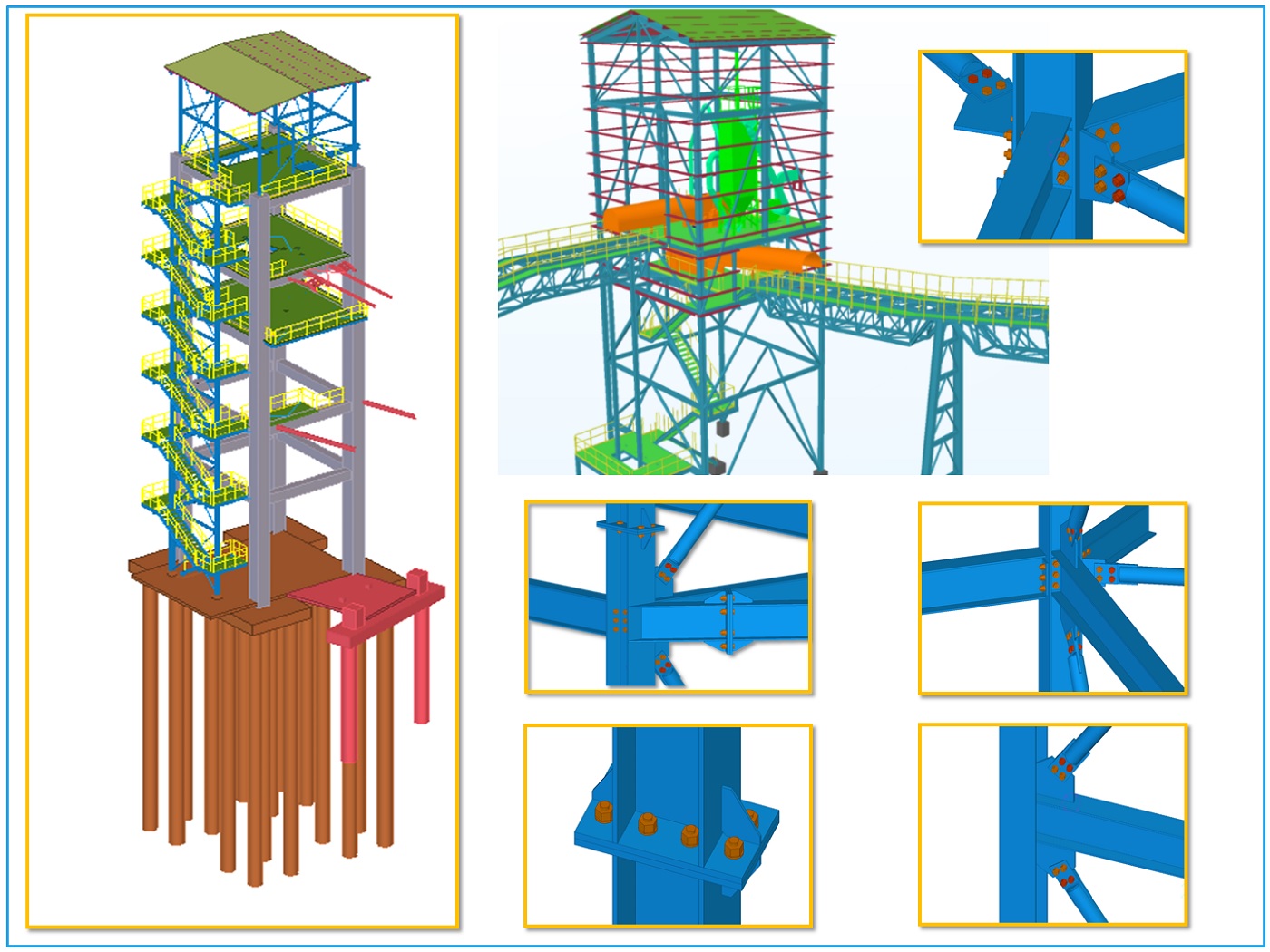

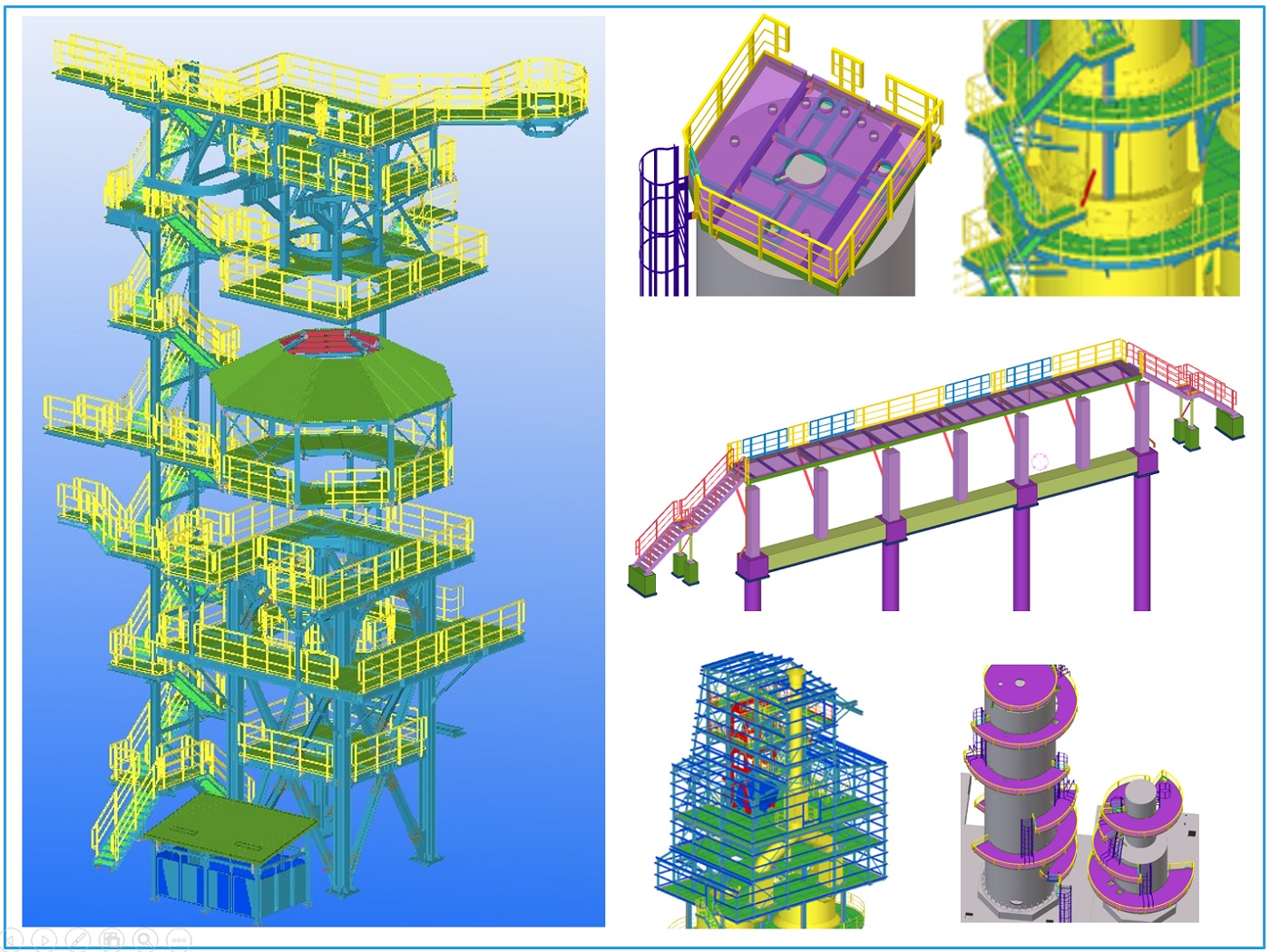

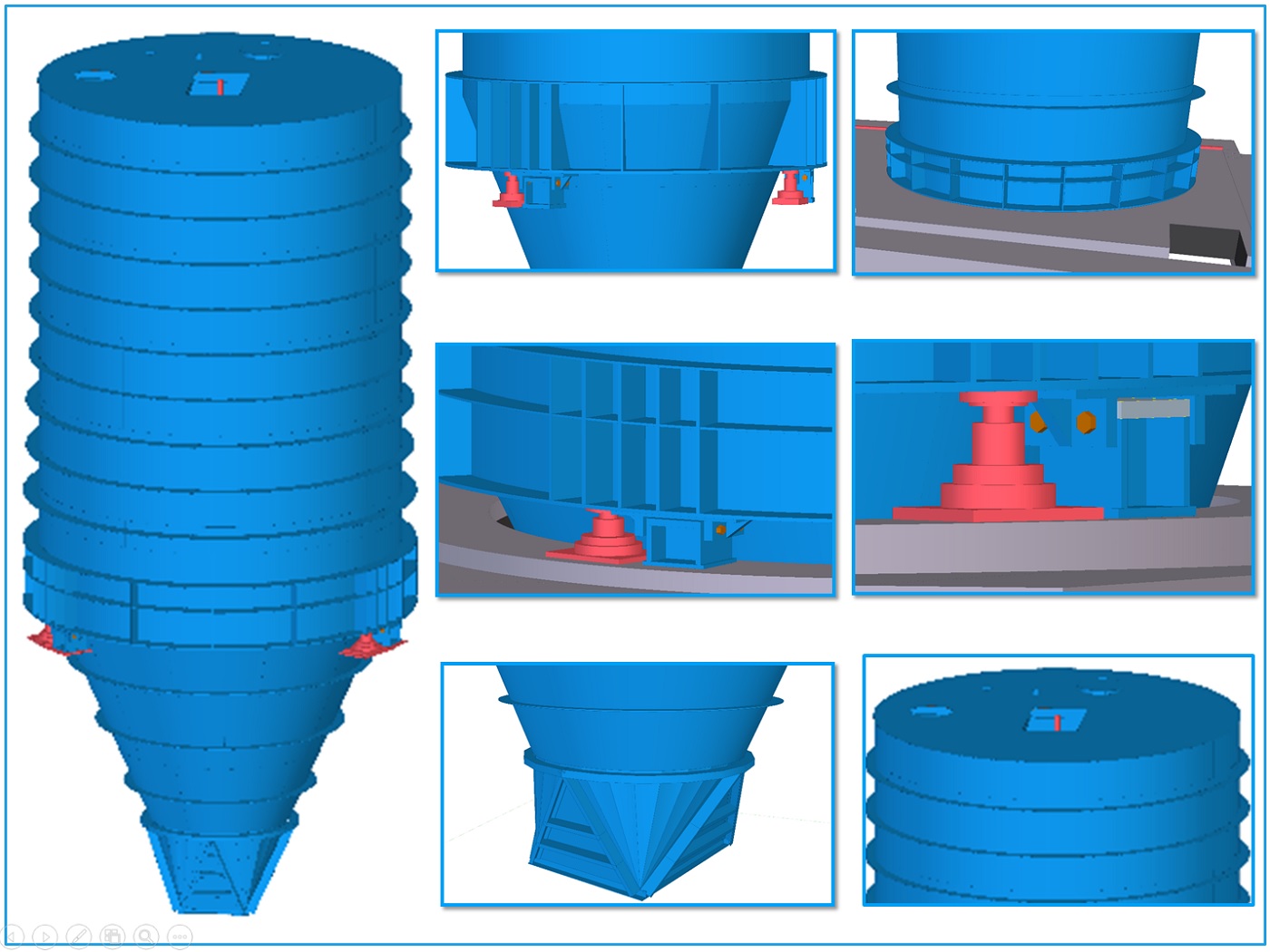

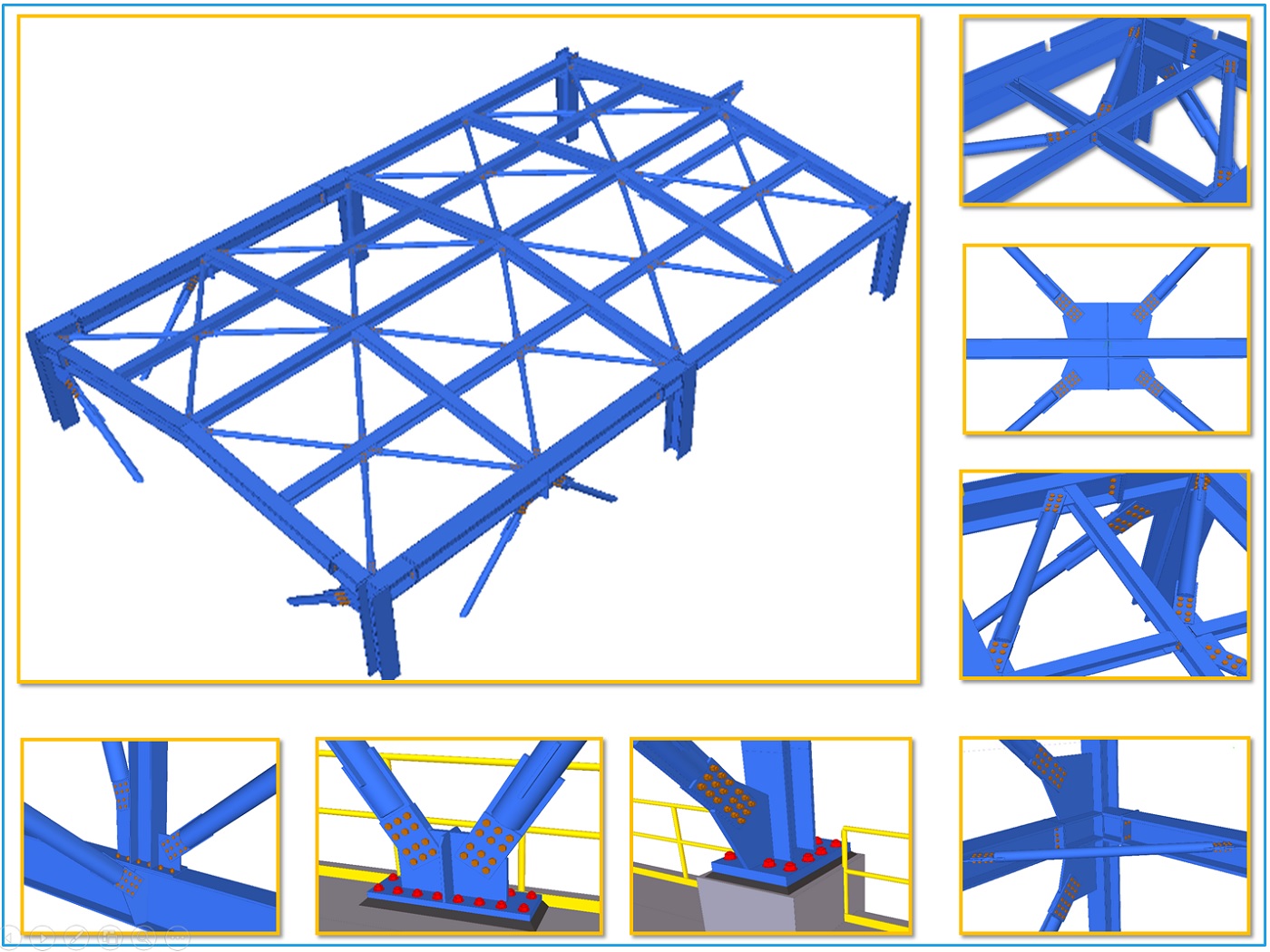

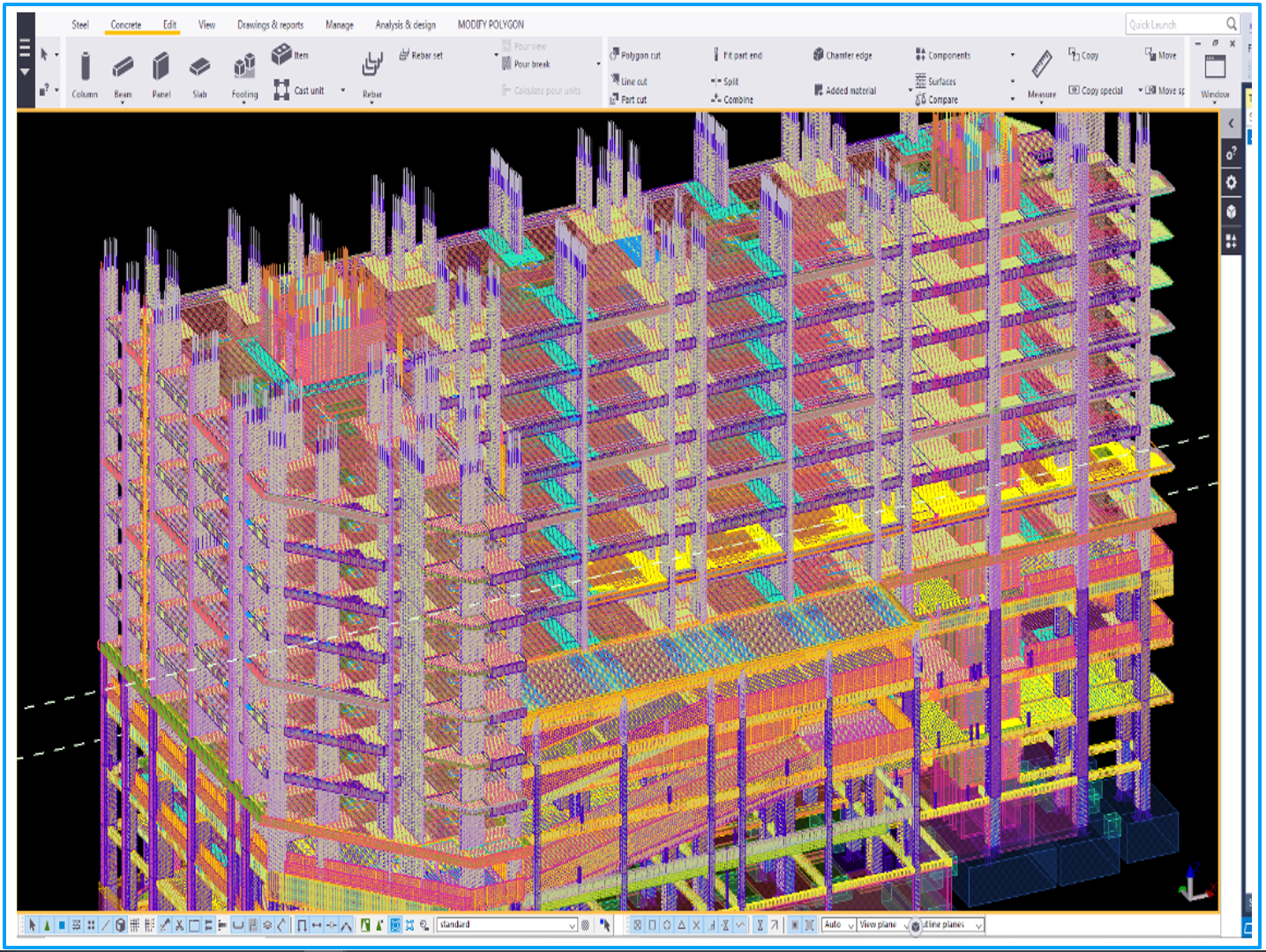

All details will be available in the 3D Tekla Structures model, as mentioned in the previous page

Step 3-Issue Workshop Design Package (WDS):

All necessary documents for fabrication will be generated from 3D model, including: Assembly drawing, single part drawing, material lists (for ordering & fabrication) & NC file.

Step 4-Issue erection drawing: This drawing is also generated from 3D model but in different period with WDS due to the fact that the erection works will be done after fabrication.

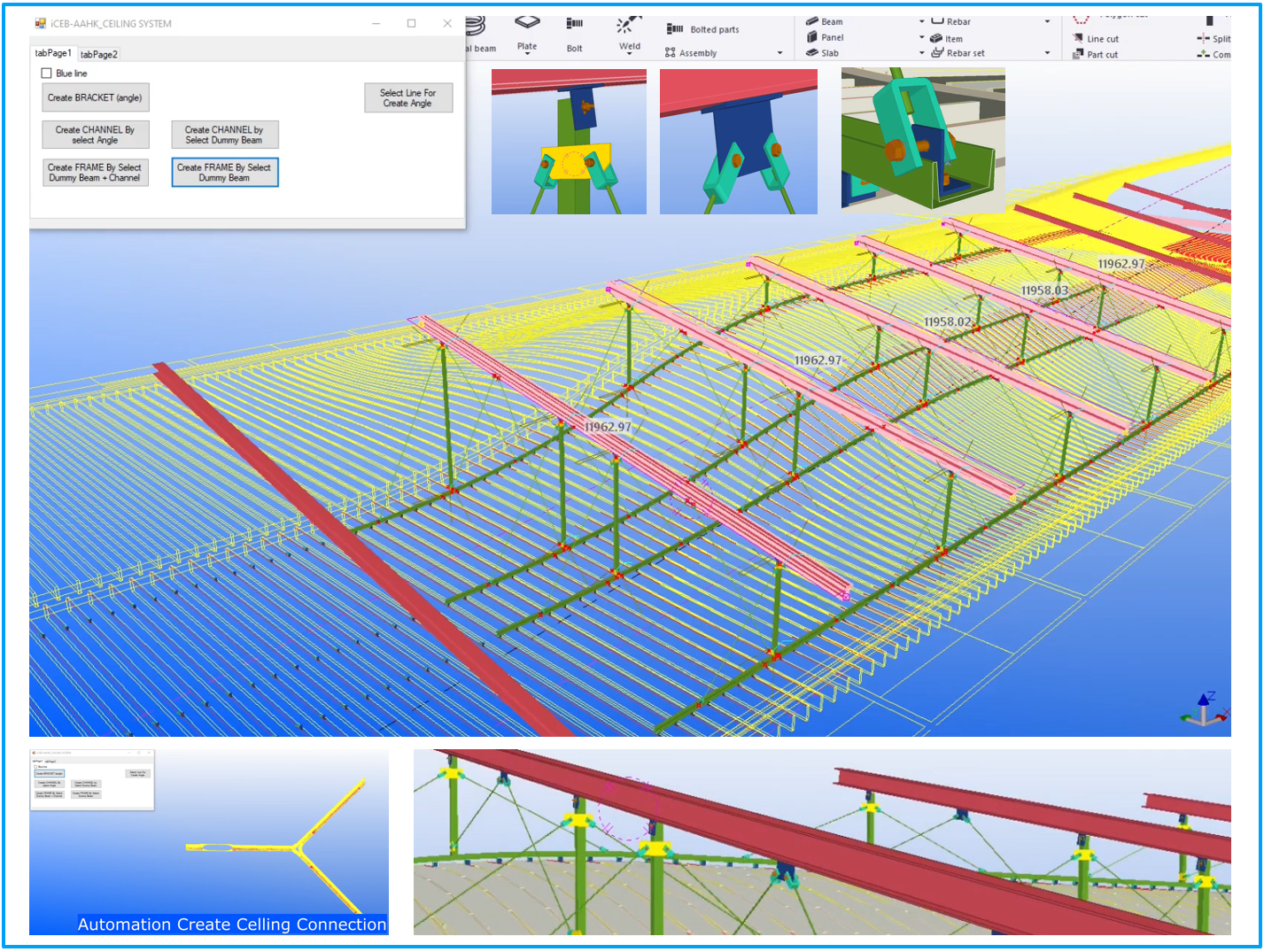

Automation

Thanks to the advantages of 3D/ BIM method, we are applying many tools to automatically built the 3D model with connection details, and generate drawings. It helps to increase the engineering efficiency, as well as to achieve high quality products with shorter time schedule.

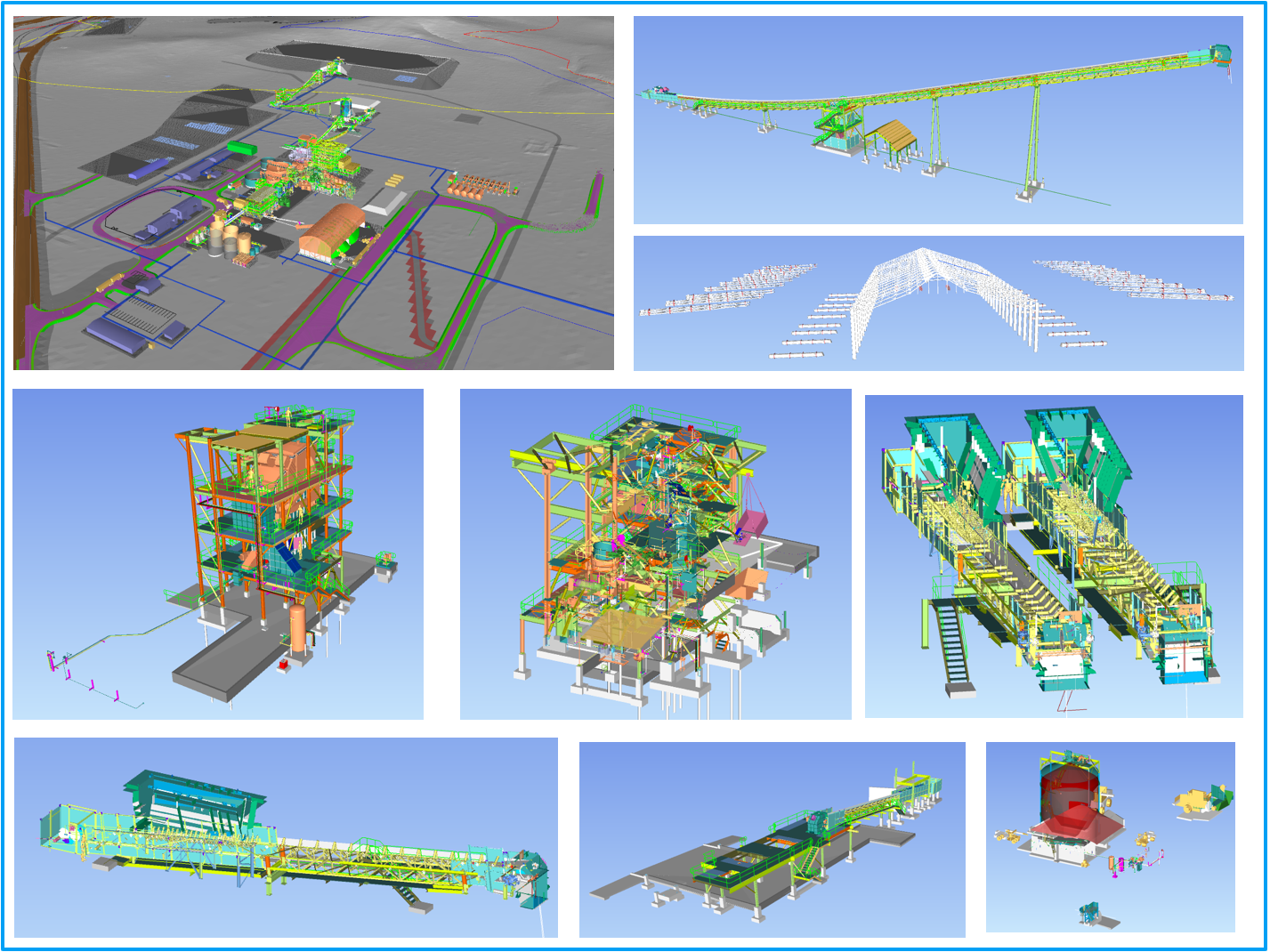

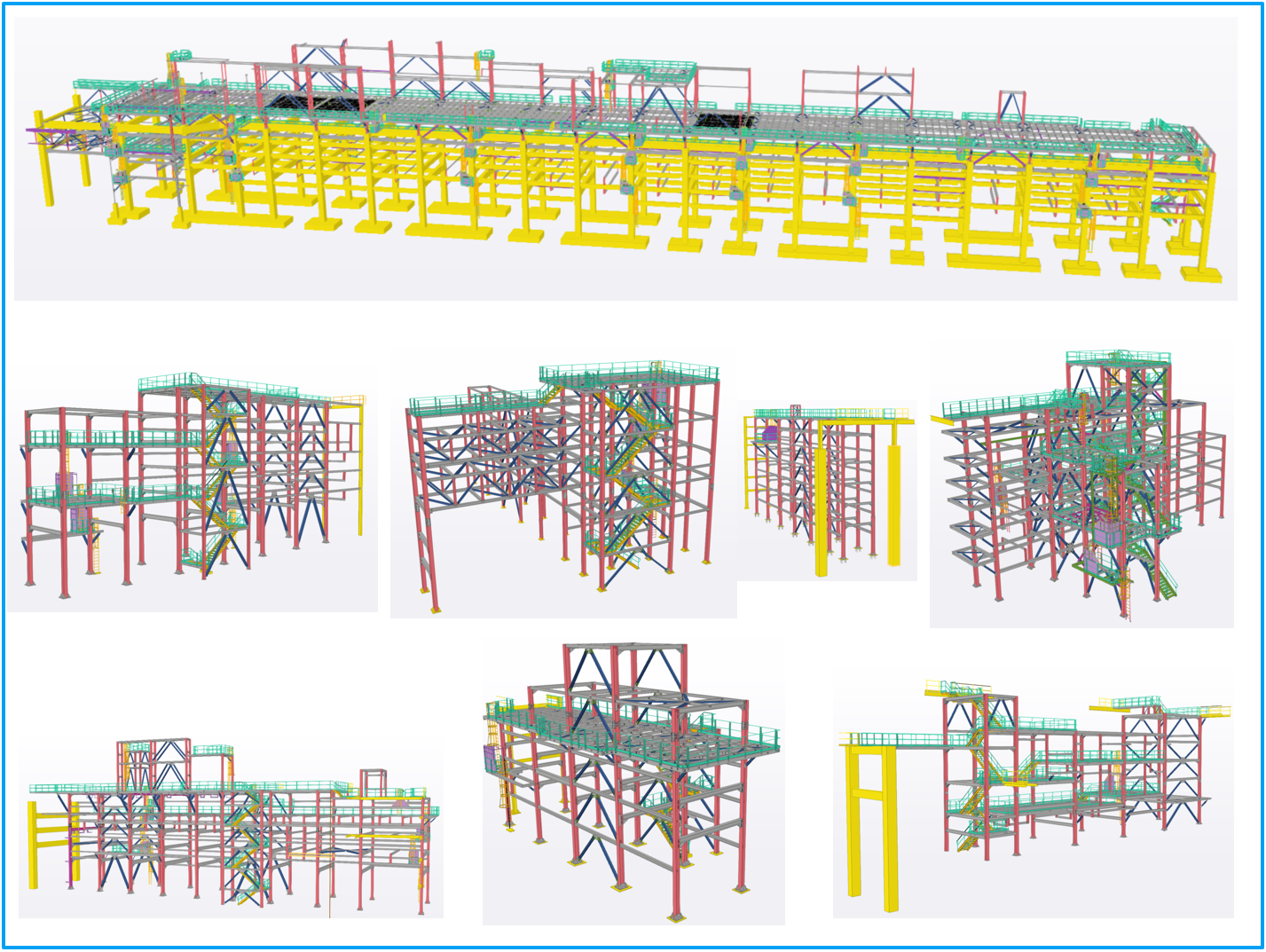

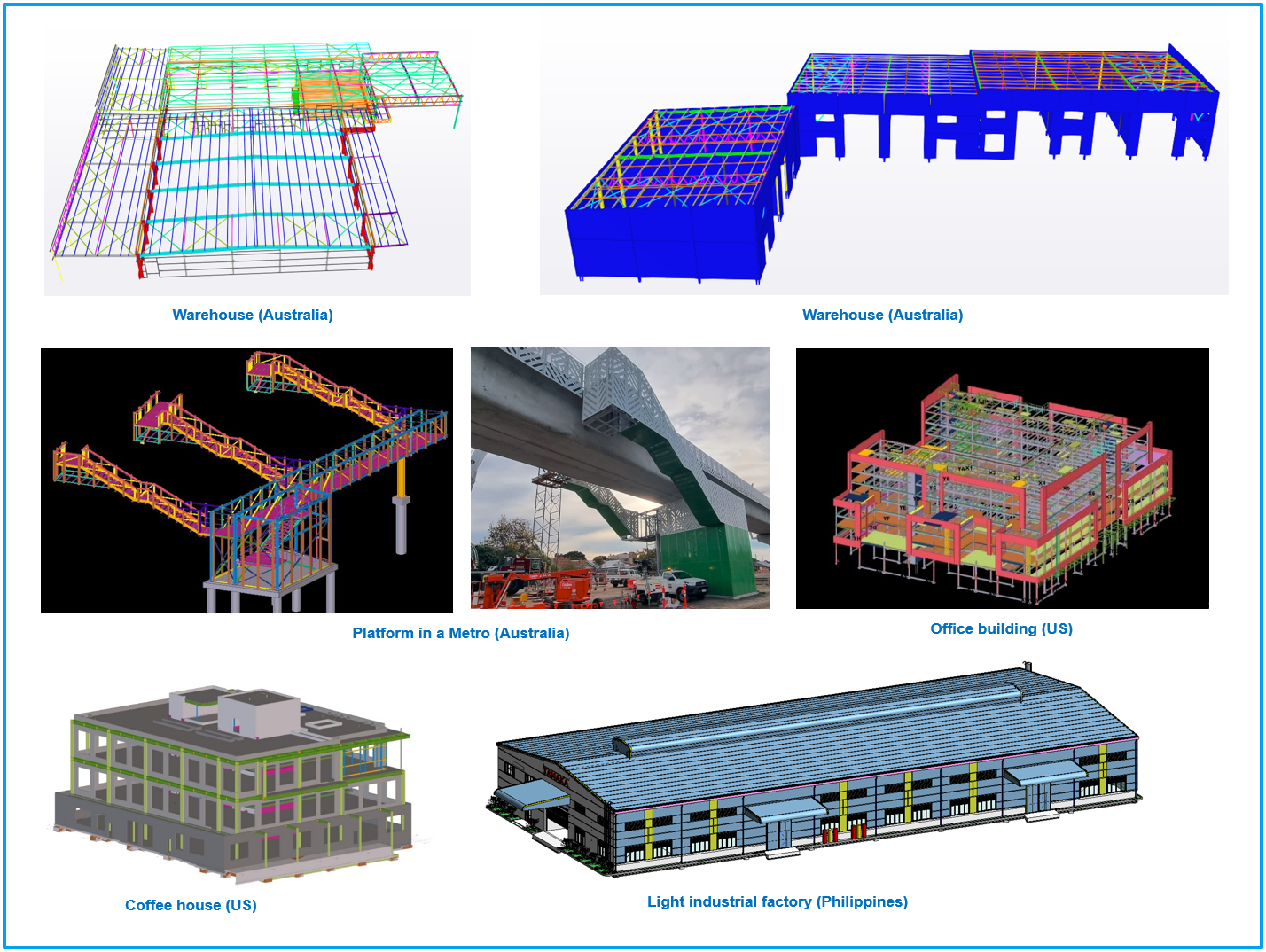

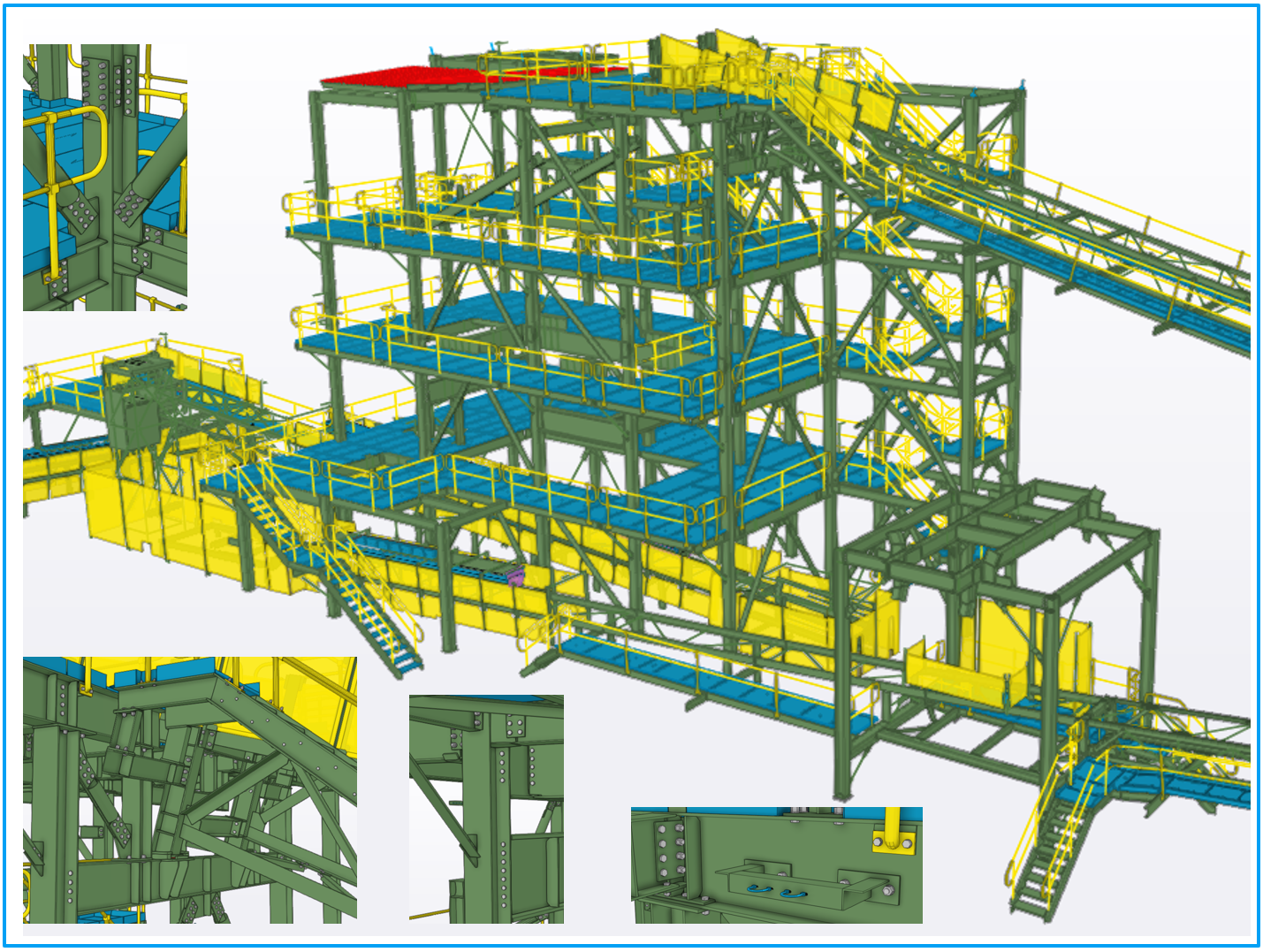

Typical 3D/ BIM Structural Steel Detailing Projects