Since 2010, our team has employed 3D/ Building Information Modeling (BIM) for the concrete/ rebar works of heavy industrial plants, buildings, infrastructure, and engineering systems in collaboration with international engineering firms and builders from developed nations, such as ThyssenKrupp (Germany), Sumitomo Mitsui (Japan), JGC (Japan), Hyundai Engineering (Korea) and Industrial Engineering Corporation (Vietnam).

With a strong engineering foundation, construction site and extensive hands-on regional and global BIM experience to implement more than 100 large-scale projects in 25 countries, we are confident in providing cost-effective and high-quality BIM solutions to owners, design firms, constructors, as well as manufacturers and suppliers worldwide.

SECTORS:

iCEB Solutions Vietnam provides our 3D/BIM rebar services for Industrial Plants (Cement, Chemical, Mining), Infrastructures (Metro & Bridge) and Residential & Commercial buildings in many countries in Australia & New Zealand, Europe, US, South America, Middle East, Asia, Africa etc. following international and local standards.

(Cement, Mining, Chemical)

(Metro & Bridge)

Buildings

(Cement, Mining, Chemical)

(Metro & Bridge)

Buildings

CONSTRUCTION METHODS:

Our 3D/ BIM rebar services are for different types of rebar construction, including Modular Solutions, Precast and Cast-In-Place.

OUR CLIENTS:

iCEB has been providing this service to design offices in Australia, New Zealand, Europe, and Asia.

Designers provide us with calculation notes, markup drawings, sketches, and point clouds of existing projects as inputs to build 3D models. From these models, we generate 2D design drawings.

The output of our work in Vietnam will serve as a crucial input for rebar prefabricators in off-site plants across Asia, Europe, and Australia. This will enable them to successfully manage all steps in their rebar project lifecycle, including material purchasing and control, cutting and bending, loss rate optimization, transportation, and logistics.

iCEB provides contractors and rebar fixers in Asia and Australia with 3D models and shop drawings for concrete and rebar. These serve as valuable inputs to effectively manage site installation, quantity control, quality control, acceptance, and payment for large-scale projects such as metros, bridges, and high-rise buildings.

SERVICES:

We assist clients in developing appropriate 3D/ BIM models from the onset of project development to achieve cost-effective, high-quality, and safe outcomes, being proactive and staying ahead of milestones.

iCEB provides the following 3D/ BIM services for concrete/ rebar works:

- 3D Modelling & Shop Drawings in all Level of Developments.

- Plug-in, Tekla Open API for Modelling & Drawings Automation.

- BIM Tools for Fabrication & Construction.

- Site Supervisor & Technical Supports.

- 3D Simulations for Installation & Construction.

Service 1: 3D Modelling & Design/ Shop Drawings

Complete 3D model without major clash

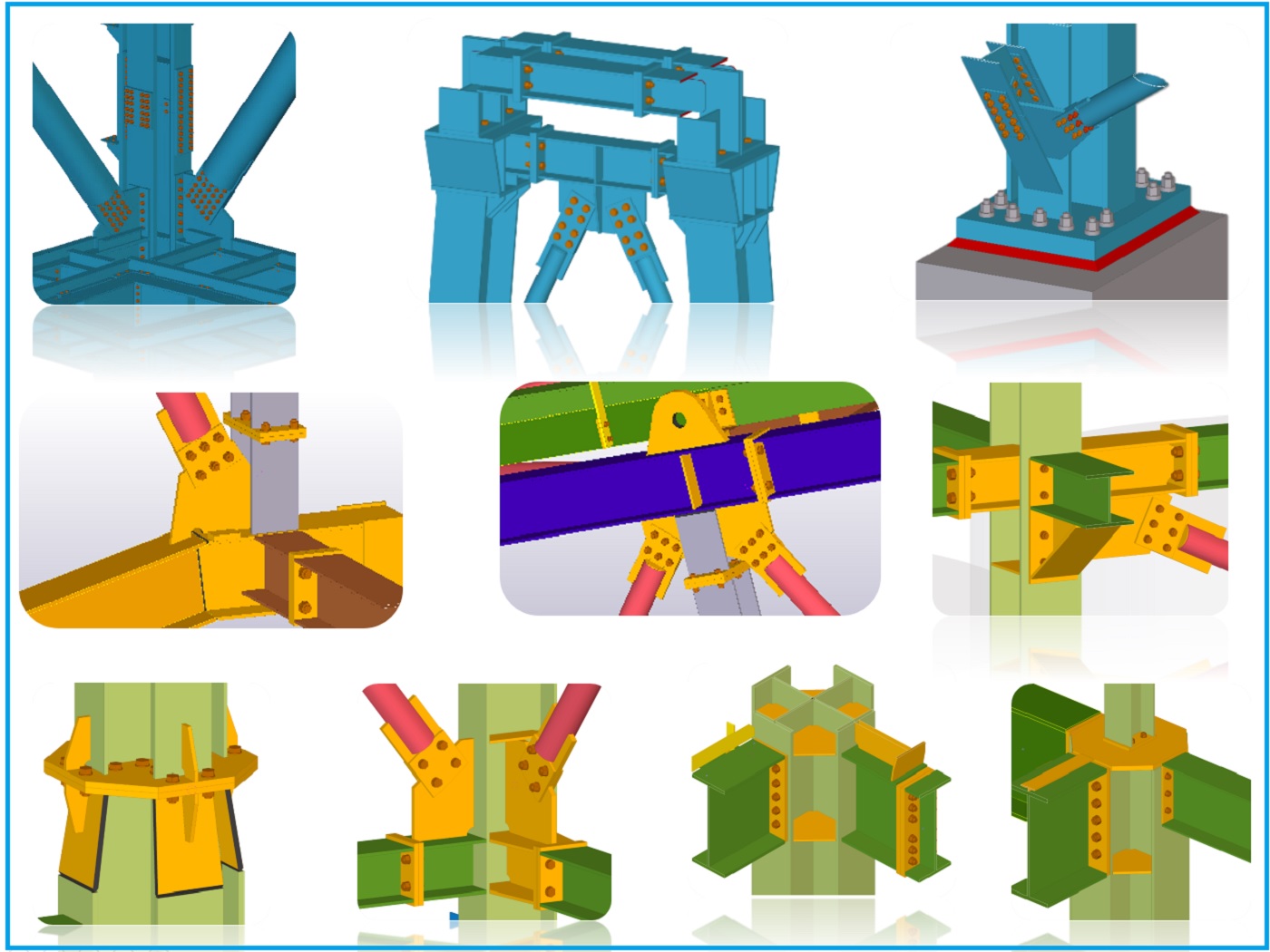

In our services for industrial plants, all details are combined in only ONE 3D MODEL including equipment, piping, duct, architectural details, foundation, upper structure, concrete, rebar, embedded steel part, pre-stress cable, structural steel, cladding, metalwork, bolt, nut, etc.

This method will allow all project’s stakeholders to foresee all majors clashes, in order to find the best solutions in the engineering phase, so that most of the difficulties in the construction phase will be eliminated in advance to ensure the Quality, Time Schedule and Cost of the projects.

High quality drawings

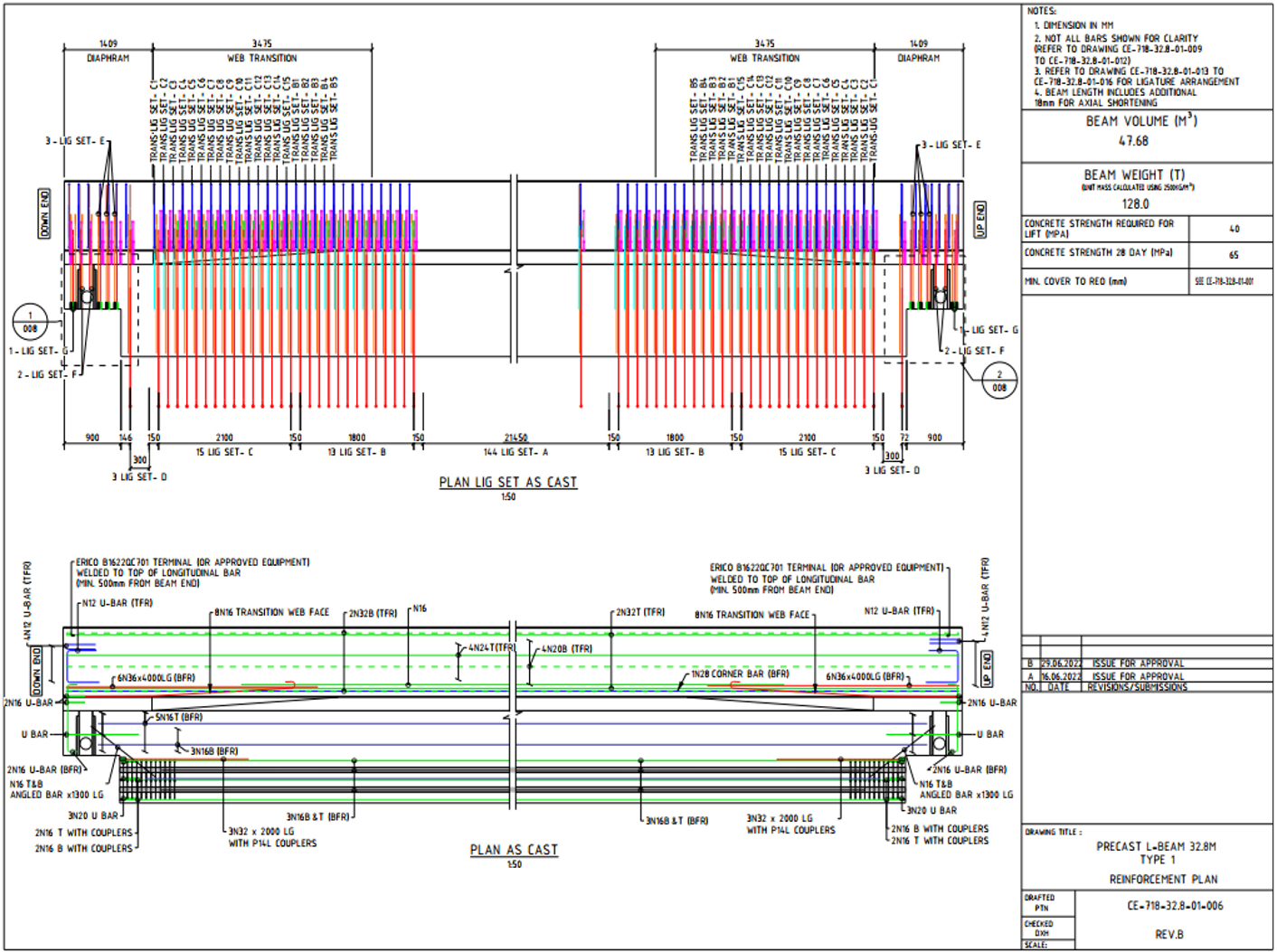

Drawings are generated directly from the 3D model with the highest quality to ensure no different parameter of one object in all drawings.

3D views and details of the complicated structures can be shown in the 2D drawings, in order to help all stakeholders to implement their works in easier way.

Different parameters of rebar can be presented by different color in the drawings, in order to facilitate in the best way for the cut & bend in the workshop and installation work on site.

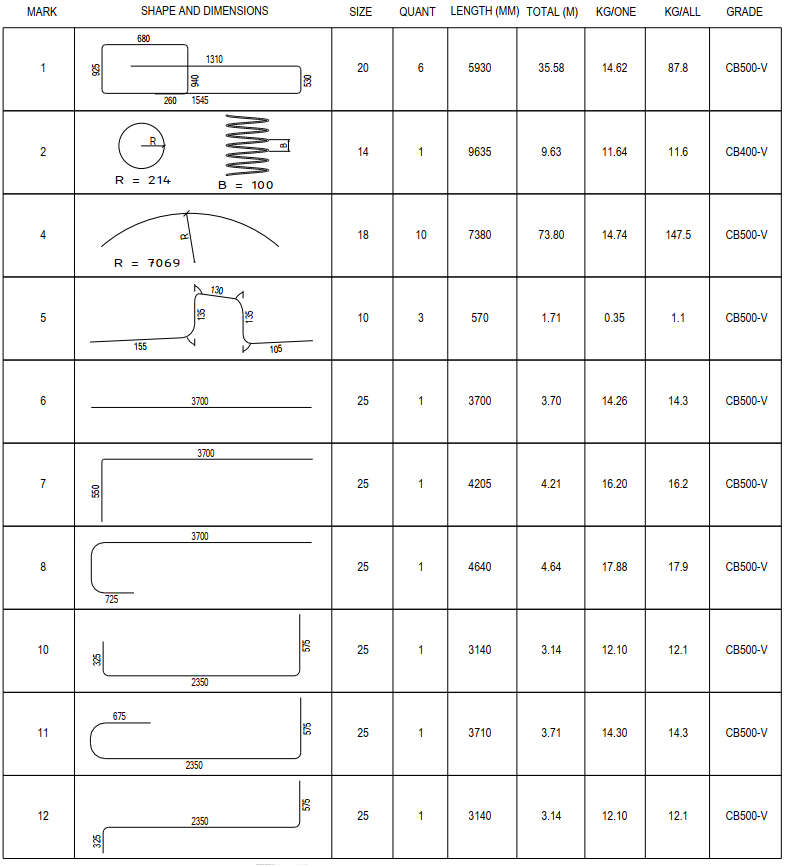

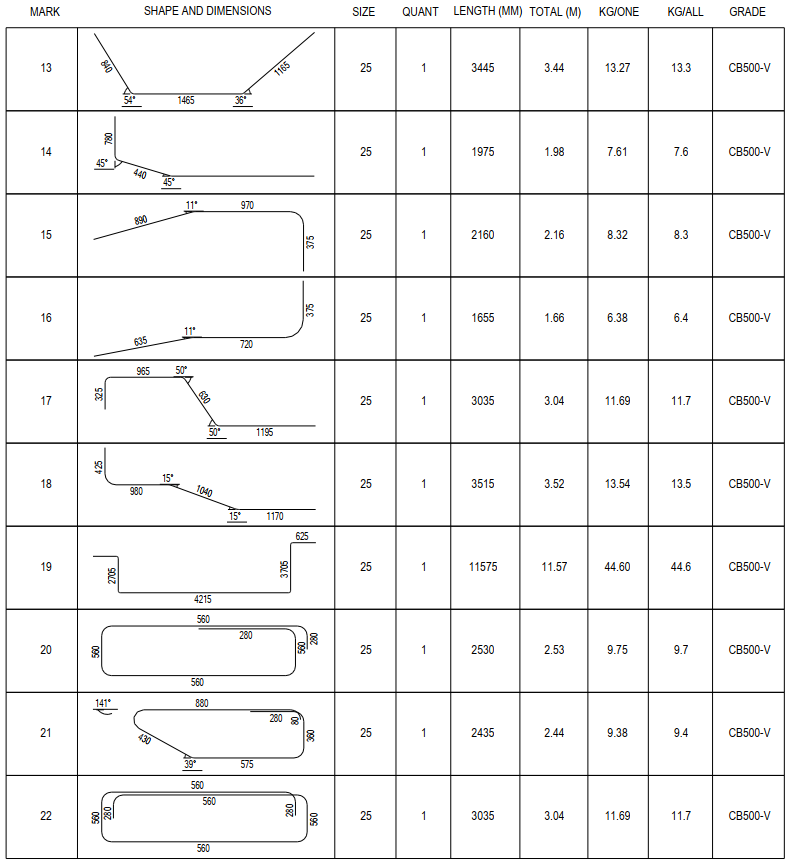

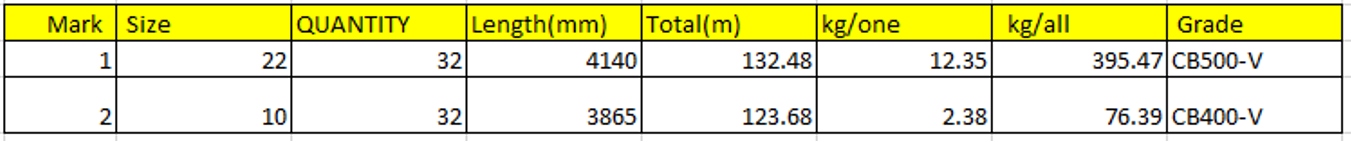

Correct bar bending schedule (BBS) without any mistake

The bar bending schedule (BBS) is automatically generated & linked with the 3D model to achieve the absolutely correctness level without any mistake of rebar parameters (mark, number, weight, length, shape, dimensions, etc.), following any required standards. We can export the rebar’s parameters in the BBS to .bvb, .abs, bvbs & ifc files, create barcode and import to the cut & bend machines for automatic rebar fabrication in the OFF SITE plants.

The below BBS is generated from 3D Tekla model, following BS 8666-2005: BBS – Bar Bending Schedule according to BS 8666-2005:

High precise level for all details

The accurate data and correct bar bending schedule without mistake ensures less errors for cut and bend works in the prefabrication yards as well as the rebar installation in the construction sites, in order to optimize the effort for the project.

Quantities control

The quantities can be easily generated from 3D/BIM model with 100% correctness level for specific area with each rebar type.

Typical 3D/ BIM rebar detailing projects

iCEB has been providing 3D/BIM rebar modeling services to clients worldwide, including in Australia, New Zealand, Europe, the US, South America, and Asia. Below are some example projects:

The Modular Rebar Solution is a highly professional method that iCEB plans to prioritize in its business development over the next few years. In this method, structures (foundation, starter bars, walls, columns, beams, slabs, etc.) are divided into typical elements to be fabricated in the workshop, transported to the site by truck, and primarily installed using cranes at the construction site.

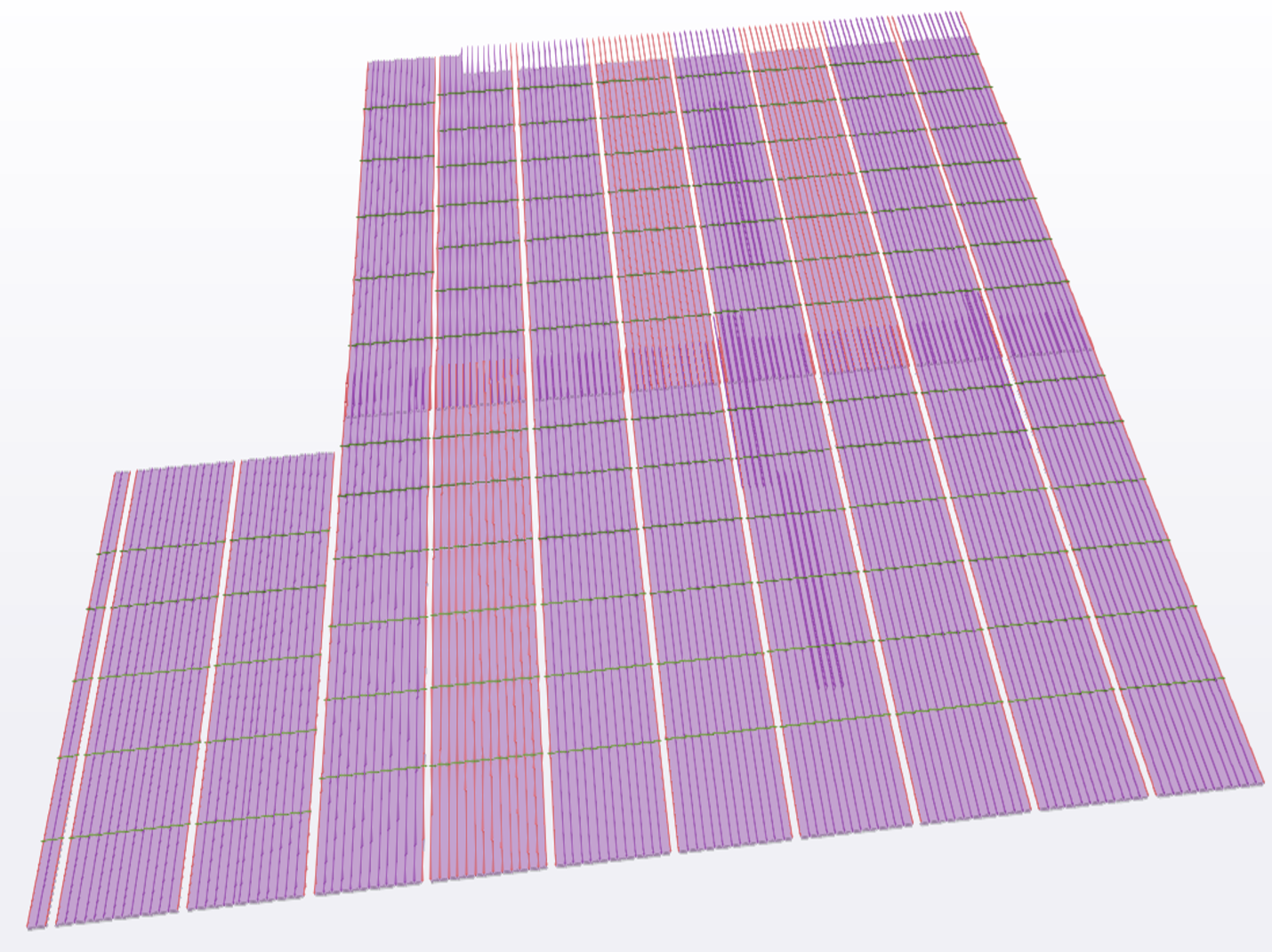

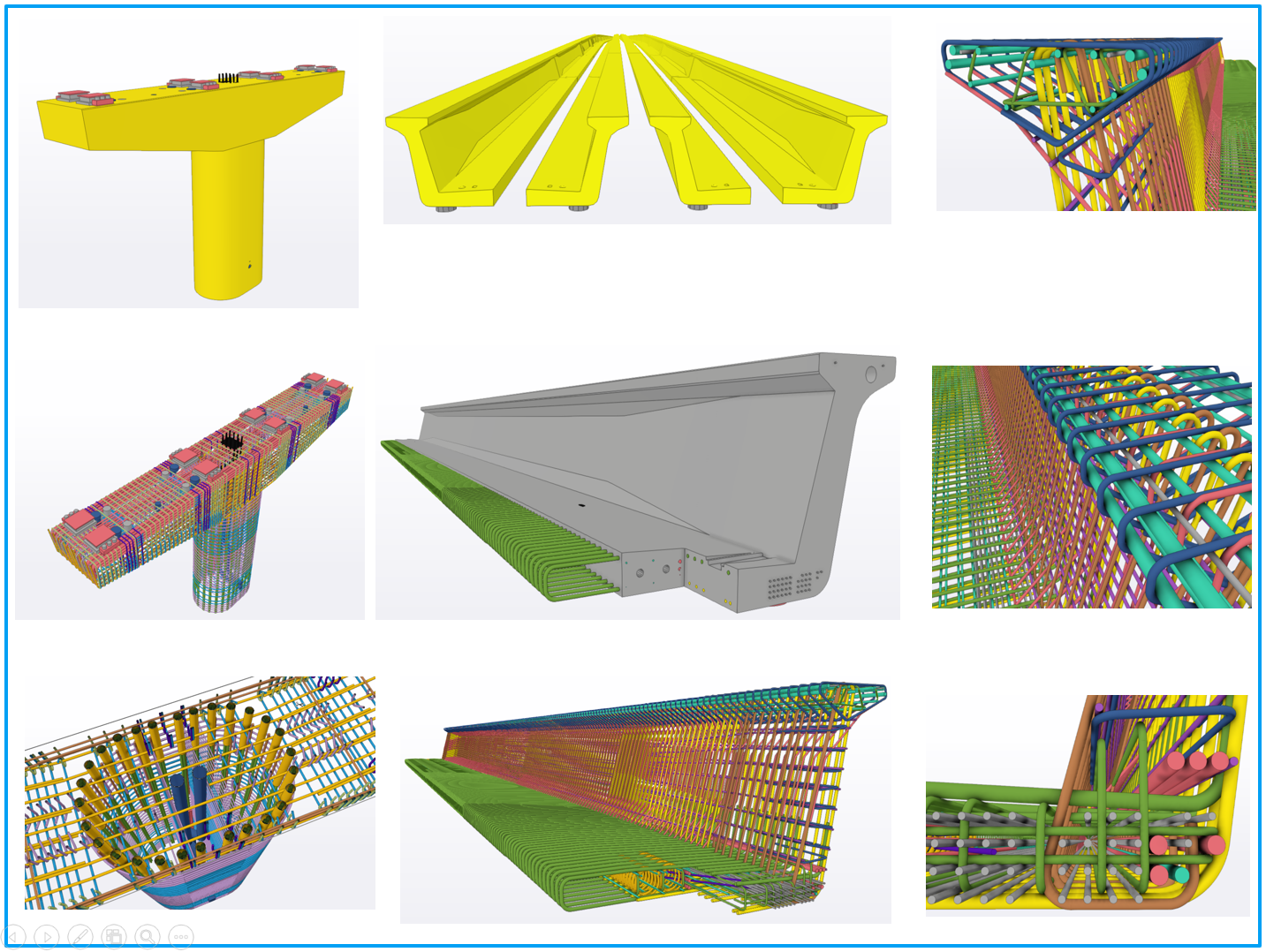

iCEB Solutions Vietnam has been providing 3D rebar modeling and shop drawings for large-scale bridge projects in Australia & New Zealand, utilizing the precast construction method. The inputs for these projects are 2D design drawings. The outputs include 3D models of the bridges, including beams, piers, crossheads, and other elements. These models ensure clash-free integration of all components, consist of rebars, anchor bolts, prestress cables, ducts, and embedded steel parts. Additionally, color drawings, bar bending schedules (BBS), and concrete quantities are generated from the 3D models.

The parametric modeling method is applied to this project, with 80% of the work, including concrete, rebar, and prestress tendons, being completed in Grasshopper software before being transferred to Tekla Structures. By consolidating all details into a single model, many major clashes, especially between prestress tendons and rebars, are identified and resolved. The bar bending schedules (BBS) are generated automatically from the 3D model according to BS8666 standards. The Bvbs file is sent to the off-site plant for digital fabrication. Notably, the contractor uses the 3D model directly for rebar installation at the construction site, eliminating the need for traditional drawings.

This residential and commercial building comprises 26 floors with two basements, utilizing piling foundations. A key highlight of this project is the successful installation of a large transfer beam (3 meters in height, 20 meters in span, and with very high rebar density) by the rebar fixer without any difficulty or need for technical clarification, thanks to the application of 3D/BIM technology. Additionally, clash-free design is applied to all main elements of the building, including piles, foundations, columns, walls, beams, slabs, stairs, and more, providing excellent input for the rebar fixers to perform their tasks efficiently at the construction site.

In our services for industrial plants, all details are combined into a single 3D model, including equipment, piping, ducts, architectural details, foundation, upper structure, concrete, rebar, embedded steel parts, prestress cables, structural steel, cladding, metalwork, bolts, nuts, and more. The highlight of this heavily loaded building is the concrete curved beams with very high rebar density, along with large embedded steel parts for equipment. Additionally, there are numerous large anchor bolts at the top of the concrete columns, positioned clash-free with D32mm rebar to connect the steel columns above. The work is significantly easier for the contractor on-site with the completed 3D model.

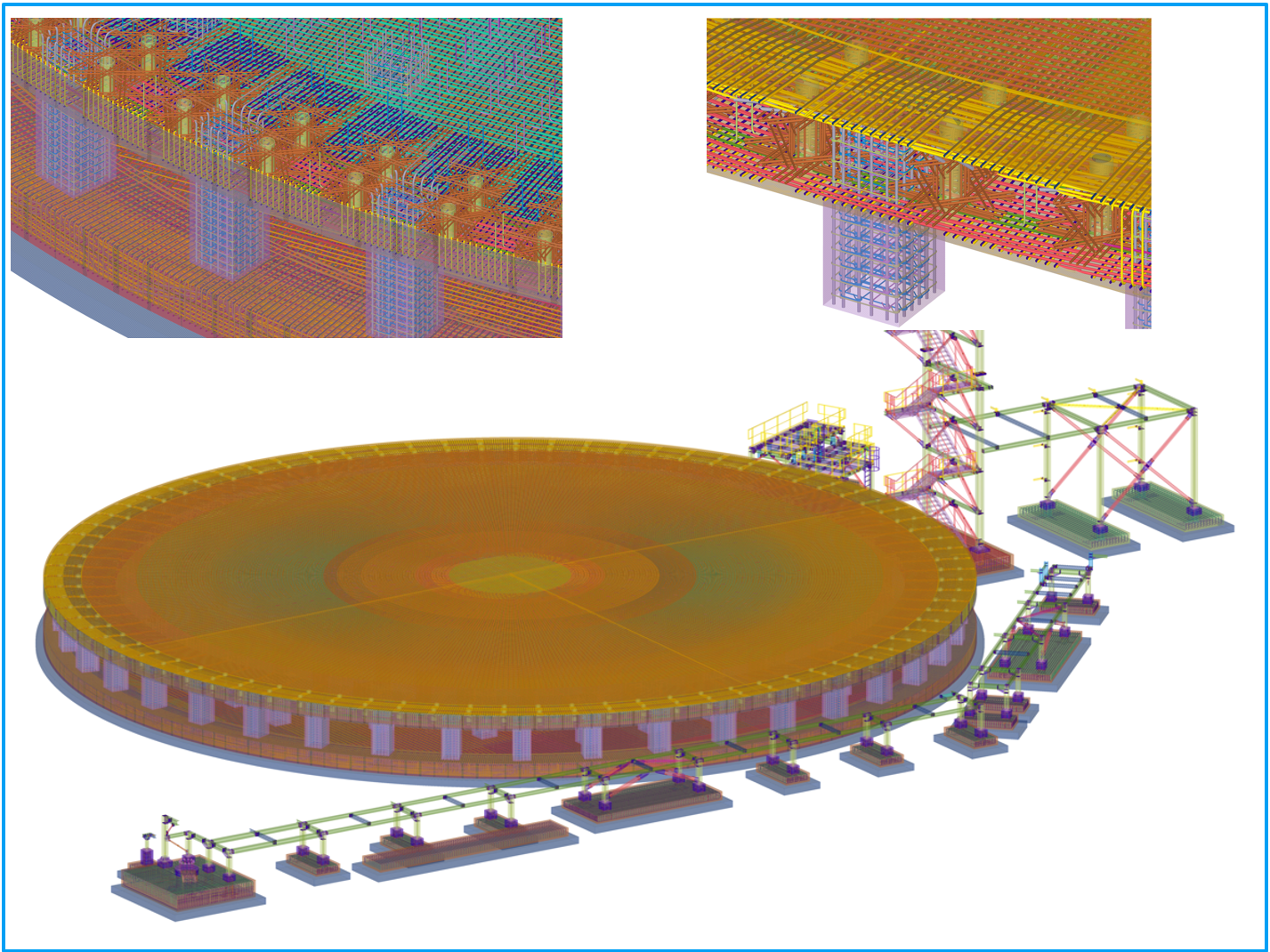

The foundation diameter is 50 meters, supporting the equipment or structural steel above. The 40mm diameter rebars, with very high density, are developed from the center to the outer perimeter of the foundation. At the foundation’s perimeter, large diameter anchor bolts are positioned without interfering with the rebar to connect the tank above. Due to the complexity of the details, the design was clarified and adjusted several times during the detailing phase to facilitate the contractor’s work at the construction site. Ultimately, we achieved a clash-free model for all elements of the foundation, including the high-density rebars, starter bars, and large anchor bolts to connect to the equipment or structural steel above.

The silo has a height of 100 meters and a diameter of 20 meters. The wall thickness is 0.8 meters, reinforced with prestressed cables and a high density of rebar. We offer professional 3D/BIM civil and structural steel engineering and detailing for silos, providing all details in a single model. It is happy to see how a well-designed model facilitates smooth operations at the construction site.

The crusher is approximately 15 meters deep from ground level, with a bottom slab and wall thickness of 1.0 meter. The hopper has a complex geometry, featuring four faces with different slopes. Thick lining steel plates are embedded in the concrete hoppers at various points, ensuring they do not clash with the high-density rebars.

The concrete walls for the basements of a high-rise building, measuring 146 meters in length, 40 meters in width, and 30 meters in height, are divided into standard diagram walls with dimensions of 1.2 meters in thickness, 6.2 meters in width, and 30 meters in height. iCEB developed automation tools to generate the 3D model and the drawings automatically for these diagram walls.

Service 2: Plug-in, Tekla Open API for Modelling & Drawings Automation

Over more than 14 years of working with design using BIM, we have developed a rich set of automation tools and plugins for 3D modelling & drawings automation

The tools enable us to deliver 3D/ BIM rebar services with both speed and high precision. These tools and plugins can be further customized according to the client’s requirements. Additionally, our engineers are experienced senior programmers with specific technical and engineering knowledge, possessing programming skills in several popular languages.

Automation tool to export data from 2D/ 3D software such as Autocad, Sap2000, Revit, Tekla Structures, etc. to another 3D software.

In case the input data is organized in a high standard way, the tool will save considerable time of the works.

Automation tools for 3D rebar modelling of foundations, columns & beams. The tools save considerably time and provide high quality 3D rebar model.

Automation tool to group, split, lap and crank the rebar following project standards. The tool is very useful in order to achieve a clash-free model or at least, a model without major clash between rebar, which helps the works in the construction site running much more smoothly.

Automation tool to generate the rebar drawings of columns.

The lost rate for rebar cutting can be optimized directly in the 3D model until expected level for defined area. The tool can also point out the cutting combination, lost rate for each rebar diameter as well as the overall lost rate ratio. The figures can be generated to excel file or text file for next steps of rebar cut & bend activities.

Plug in to build the 3D model and generate 2D drawings of standard man-holes from design input in excel spread sheet.

Service 3: BIM Tools for Fabrication & Construction

Besides the tools for 3D modelling & drawings, iCEB has been also providing the BIM tools in order to help the fabricator & contractor to manage their works in the fabrication workshop & constructions sites:

The progress of the rebar fabrication works in the factory can be controlled well following 3D/ BIM concept for different steps, including: workshop drawings, material procurement, cut & bend, marking, packing and transporting. The data can be generated to different 2D reports with detail level required.

The quantities can be generated automatically from 3D model to the required Bill of Quantity form, thanks to a plug-in and the fact, that the data in the 3D model is well organized following company standards. The quantities then, can also be exported to the required pricing software for price analysis.

Service 4: Site Supervisor & Technical Supports

Not only limiting in the 3D/ BIM detailing phase, iCEB is also offering the clients the possibilities to send our experience engineers, who have been working on large scale construction sites, to work as the supervisors/ technical advisors at the construction site or offsite rebar fabrication workshops in other countries.

On behalf of the client, our engineers will communicate with all involved parties including iCEB office in Vietnam, in order to run the project in the most efficient way.

iCEB has been sending our experienced site engineers to work oversea in large scale projects. These site engineers will communicate directly with all involved parties in the construction sites in order to understand well all technical requirements as well as the construction methods and then, coordinate with the detailing team in Vietnam to provide the best 3D detailing services. It is also very good for the detailing team in Vietnam to get the feedback/ experience from the site engineers as the good input to provide the deliverables which can be easily implemented in the construction site without any major difficulty.

Beside the detailing services, iCEB also sent our experienced engineers to work in the fabrication workshop in Vietnam to supervise the work there on behalf of the clients in other countries. The fabricated rebars then being packed in the container and transported to Australia by shipping.

On behalf of the client, our engineers will supervise all the works in the fabrication workshop including checking input material, cutting & bending according to the required standards, packing in the containers and then, transporting to the ships.

Service 5: 3D Simulations for Installation & Construction

Following the clients demands, iCEB can prepare the videos to simulate the construction sequences for rebar/ concrete works in all construction method including Cast-In-Place, Precast as well as Modular Solutions.

These simulation videos will help the contractors to foresee their works in the construction site in the detailing phase. As the results, the contractor will be able to prepare and implement their works without any major difficulties in order to save cost, accelerate the time schedule as well as to ensure the safety on site.