iCEB Solutions expects to become a BPO (business process office) of the international rebar cut and bend factories for preparing rebar drawings, respective rebar bending schedules and detailed cutting lists for worldwide projects with HIGHEST QUALITY by applying innovative 3D/ BIM METHODS.

The output of our works in Vietnam shall be one of the main important inputs for rebar prefabricator in the OFF SITE plant, rebar fixer, main contractor, consultant and investor to manage successfully all steps in rebar project’s lifecycle, including: material purchasing & controlling, cut and bend, lost rate optimization, transportation & logistic, site installation, quantities control, quality control, acceptance and payment, etc. This is really the strong point of 3D/BIM and will bring very high benefit to all project’s stakeholders regarding QUALITY, TIME SCHEDULE & COST!

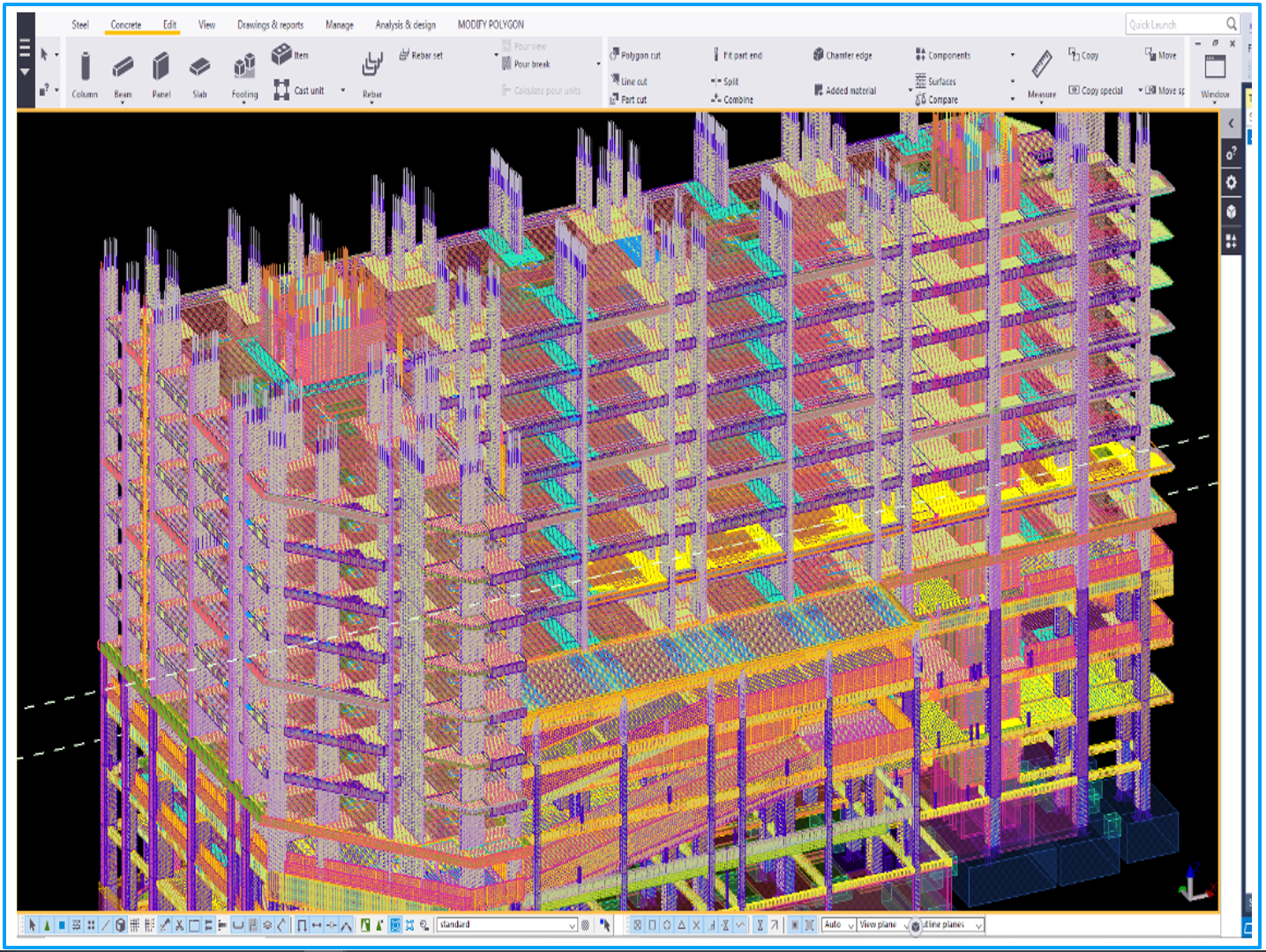

BIM applications are common nowadays and therefore, we only introduce the below contents to the prefabricators & contractors who have not applied BIM in the business:

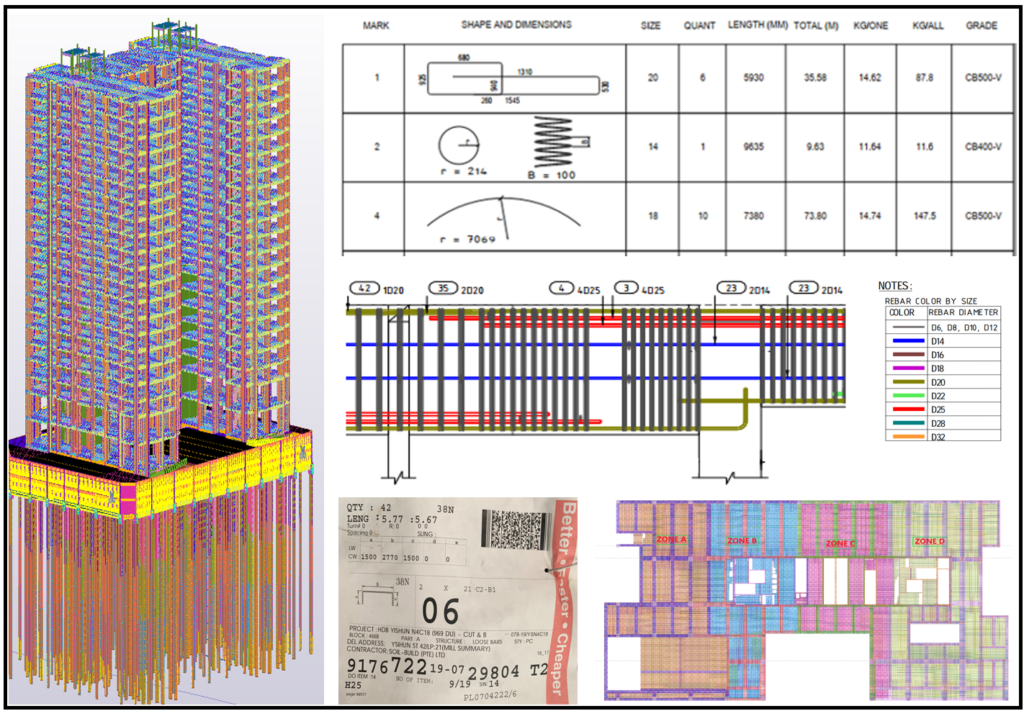

The parameters of rebars such as type, shape, dimensions, numbers, length, etc in the 3D/BIM model will be generated to the barcode document. This code is the “set up” for the bending machines in the OFF SITE prefabrication yard. Afterwards, the cut and bent rebar will be delivered to the construction site.

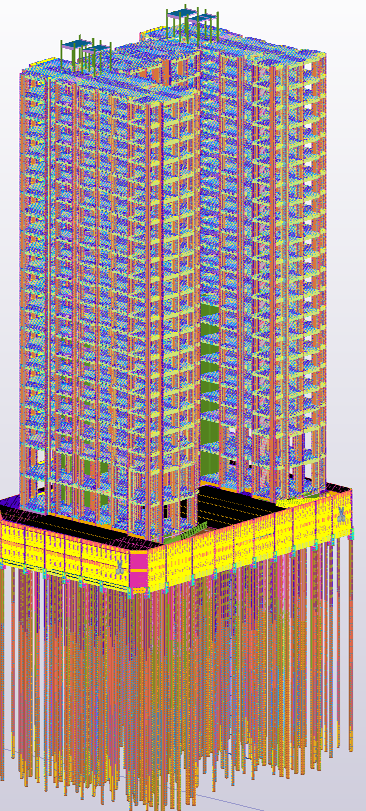

For the high-rise building like beside picture, the typical floors from 3 or 4 to 40 are principally the same. Thanks to 3D/ BIM, the rebar fabricator in the prefabrication yard, the rebar fixer and main contractor can agree how the project will be built per day to define the schedule released for rebar bending, transporting to site, fixing and concreting with the daily plan.

The actual rebar status such as engineering, shop drawings, raw material preparation, cutting, bending, transporting to the site, installation, check & acceptance, payment can be recorded and send to a 3D/ BIM central model.

The rebar status then can be generated to reports with different detail levels for the owner, project manager, main contractor, sub-contractor, rebar fixer, rebar cut & bend in the pre-fabrication yards, shop engineers, etc.

The quantities can be easily generated from 3D/BIM model. In addition, by adding more unit price of element, it allows to control the price of the project. This concept can be applied to control the acceptance and payment as well.

The Quality control will be much easier by 3D/BIM since all stakeholders can check, confirm, accept the works done by using a smart phone/ tablet on site to verify the information in the model and the actual works implemented.

Construction/ safety method statement will be presented effectively in the 3D model. All stakeholders can discuss and agree on the method in the 3D model as an advance step before the real construction activities. It is also easier to understand the details, the difficulties and the solutions for the complicated tasks on site, thanks to the video showing the construction sequences.

The 3D model of the rebar works can be shared to the cloud, so that all stakeholders can communicate together for relevant subjects.

All data in the 3D/ BIM model can be shown easily by all stakeholders for the meeting in the office, for cut and bend, transportation or the work in the construction site.

Automation Tool, Plug-in

3D/ BIM Concrete & Rebar Detailing in all Development Levels